- Products

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

How to Choose the Right High Pressure Gas Regulator for Your Application

In various industrial applications, the selection of an appropriate High Pressure Gas Regulator is crucial for ensuring both efficiency and safety. According to a recent report by the Global Gas Regulator Market, the demand for gas regulators, particularly those handling high pressure, is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2021 to 2028, driven by advancements in manufacturing processes and an increasing reliance on gas as a fuel source. The right regulator not only controls gas pressure but also improves system reliability, reduces waste, and enhances overall operational productivity. With the diverse range of available options, making an informed choice can significantly impact performance metrics and compliance with industry standards. Whether in welding, laboratory applications, or chemical processing, understanding the specifications and features of High Pressure Gas Regulators is essential for optimizing their use and achieving desired outcomes.

In various industrial applications, the selection of an appropriate High Pressure Gas Regulator is crucial for ensuring both efficiency and safety. According to a recent report by the Global Gas Regulator Market, the demand for gas regulators, particularly those handling high pressure, is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2021 to 2028, driven by advancements in manufacturing processes and an increasing reliance on gas as a fuel source. The right regulator not only controls gas pressure but also improves system reliability, reduces waste, and enhances overall operational productivity. With the diverse range of available options, making an informed choice can significantly impact performance metrics and compliance with industry standards. Whether in welding, laboratory applications, or chemical processing, understanding the specifications and features of High Pressure Gas Regulators is essential for optimizing their use and achieving desired outcomes.

Understanding the Basics of High Pressure Gas Regulators

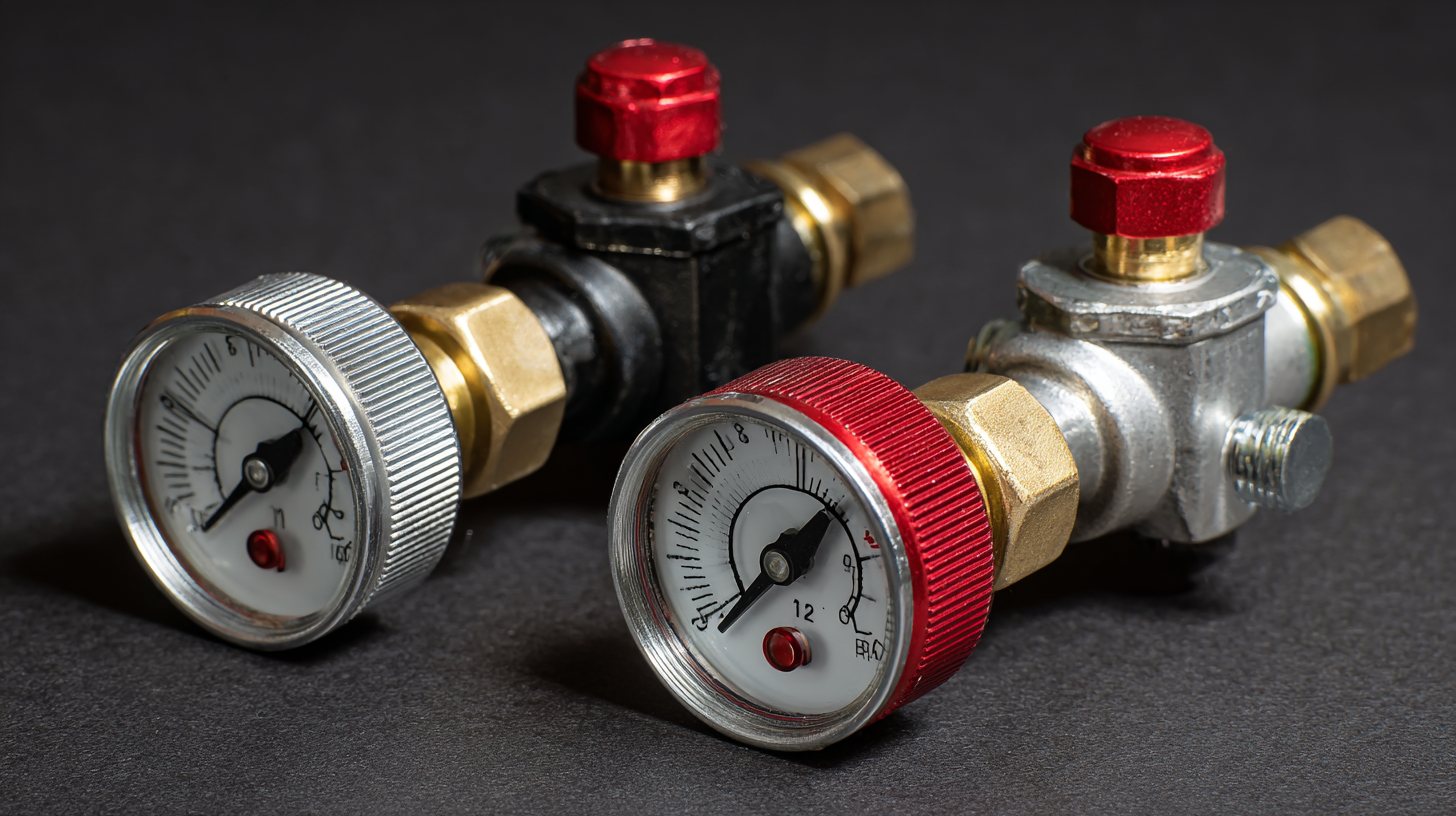

High pressure gas regulators are essential devices used in various applications to control the pressure of gases, ensuring safety and efficiency in operations. Understanding the basics of these regulators begins with recognizing their primary function: to reduce and maintain the pressure of a gas coming from a high-pressure source to a specified lower pressure suitable for the end-use application. This involves a pressure sensing element, a valve, and an adjustment mechanism that helps achieve the desired pressure settings.

When selecting a high pressure gas regulator, it's crucial to consider factors such as the type of gas being regulated, the pressure range required, and the flow rate necessary for your application. Different gases may react differently under pressure, so compatibility with the materials and design of the regulator is essential. Additionally, understanding the specific requirements of your application, whether it be for welding, medical use, or industrial processes, will guide you in choosing a regulator that not only meets your pressure needs but also performs reliably and safely under varying conditions.

High Pressure Gas Regulator Specifications Comparison

This chart compares the specifications of four different high pressure gas regulators based on their maximum outlet pressure and flow rate. Choosing the right regulator is essential for efficiency and safety in your gas application.

Identifying the Specific Requirements for Your Application

When selecting a high pressure gas regulator, the first step is to clearly identify the specific requirements of your application. This involves understanding the type of gas you will be using, as different gases have unique properties that can affect performance and safety. For example, some gases may require regulators made from specific materials to prevent corrosion, while others might need regulators that can handle higher temperatures.

Additionally, consider the pressure range required for your application. It’s essential to match the regulator’s inlet and outlet pressure specifications with the operational needs of your system. Ensuring that the regulator can accommodate peak pressures without compromising safety is crucial. Furthermore, assess factors such as flow rates, connection types, and environment, as these elements will dictate not only the appropriate regulator model but also the overall efficiency and effectiveness of your gas management system. Understanding these specific requirements helps make an informed choice that enhances safety and performance.

How to Choose the Right High Pressure Gas Regulator for Your Application

| Parameter | Description | Importance |

|---|---|---|

| Inlet Pressure Range | The range of inlet pressures the regulator can handle. | Critical for ensuring the regulator operates effectively within system limits. |

| Outlet Pressure Range | The range of outlet pressures the regulator can provide. | Essential for controlling the downstream pressure within application requirements. |

| Flow Rate | The maximum flow rate that the regulator can deliver. | Important to match with application demand to prevent pressure loss. |

| Temperature Range | Temperature limits within which the regulator can operate. | Important for ensuring safe and reliable operation under varying conditions. |

| Material Compatibility | Materials that the regulator is made from, and their compatibility with the gas type. | Crucial to avoid corrosion and ensure longevity of equipment. |

| Regulator Type | Type of regulator (e.g., single-stage, two-stage, etc.). | Affects control precision and response time in varying applications. |

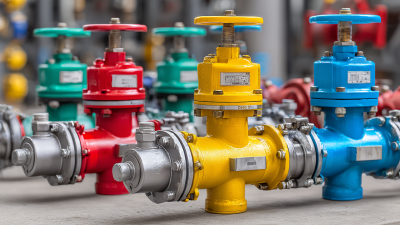

Evaluating Different Types of Gas Regulators Available

When evaluating different types of gas regulators for high-pressure applications, it's essential to understand the varying features and specifications that cater to specific operational needs. Gas regulators are critical for ensuring safe and efficient gas flow management across various industrial applications, and selecting the right type can significantly impact performance outcomes. According to industry reports, the global market for pressure regulators is expected to grow at a CAGR of around 6% over the next five years, driven by advancements in technologies and increased demand across sectors, including energy and manufacturing.

When choosing a gas regulator, consider the application requirements such as flow rate, pressure range, and compatibility with the gas type. Regulator designs vary, including single-stage and multi-stage types, each offering unique advantages depending on the system's pressure stability needs. For instance, multi-stage regulators are often preferred in environments where precise and consistent output pressures are critical.

**Tip:** Always review the technical specifications provided by manufacturers to ensure the regulator is adequate for the volume and type of gas being used.

Additionally, consider the environmental implications associated with gas systems, as highlighted in recent studies assessing the interaction between industrial processes and regulatory frameworks. Understanding both the technical and environmental aspects can help ensure compliance while optimizing system performance.

**Tip:** Consult with industry specialists to match your unique application with the right regulator, as this expertise can prevent costly errors in installation and operation.

Assessing Safety Features and Compliance Standards

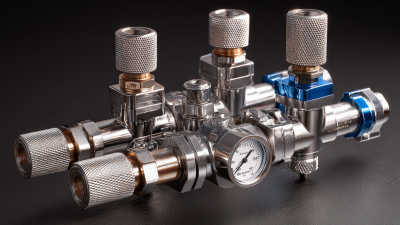

When selecting a high-pressure gas regulator, assessing safety features and compliance standards is paramount. Safety features should include pressure relief mechanisms, robust materials to withstand extreme conditions, and fail-safe designs that prevent over-pressurization. These components not only protect the operator but are essential in adhering to regulatory guidelines, which may vary by application and location.

Compliance with established standards is crucial for ensuring that gas regulators operate safely and effectively. Regulatory bodies often implement self-audit programs to encourage manufacturers and users to evaluate their adherence to safety standards. This proactive approach aligns with international compliance initiatives seen in various sectors—from food safety measures that influence agricultural practices to the frameworks guiding the use of automated vehicles. By integrating these compliance standards into the selection process, users can ensure reliability and safety in their operations, minimizing risks associated with high-pressure gas systems.

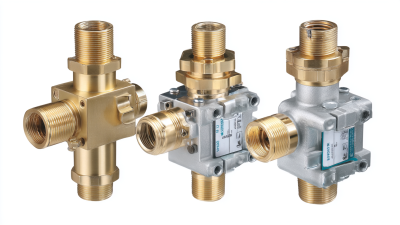

Determining the Right Size and Flow Capacity for Your Needs

When selecting a high pressure gas regulator, understanding the right size and flow capacity for your specific application is crucial. According to a report by the Compressed Gas Association, ensuring your regulator can adequately handle the gas flow is vital to maintaining system integrity and efficiency. For instance, applications requiring a substantial flow rate of 10,000 SCFH (Standard Cubic Feet per Hour) will necessitate a regulator designed to manage such volumes, typically one with a larger diaphragm and port sizes to ensure minimal pressure drop.

Moreover, the International Society of Automation emphasizes the importance of matching the regulator's capacity to the peak flow demands of your application. An oversized regulator may lead to instability and inaccurate pressure control, whereas an undersized regulator can cause significant performance issues and even safety hazards. Industry data suggests that proper sizing can enhance system performance by up to 30%, thereby not only improving operational efficiency but also extending the lifespan of associated equipment. Thus, assessing both the size and flow capacity against your system requirements is essential for optimal functionality.

Related Posts

-

10 Essential Reasons to Choose the Best Gas Regulator Valve for Your Needs

-

Top Strategies for Maximizing Efficiency with High Pressure Regulators

-

Identifying Common Issues with Gas Regulators: Ensuring Safety and Efficiency in Your System

-

Top 5 Innovative Applications of the Best High Pressure Regulators in Various Industries

-

Exploring Unique Examples of Pressure Valve Applications in Industrial Processes

-

5 Essential Tips for Choosing Your Water Pressure Regulator Valve