- Products

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

How to Choose the Right Water Regulator Valve for Your Industrial Needs

In the ever-evolving landscape of industrial operations, the importance of selecting the appropriate Water Regulator Valve cannot be overstated. According to a report by MarketsandMarkets, the global water management market is projected to reach $1 trillion by 2025, underscoring the critical role that water control systems play in various sectors, from manufacturing to agriculture. Water Regulator Valves, designed to maintain consistent water pressure and prevent damage to equipment, are essential components in ensuring operational efficiency and sustainability. With a myriad of options available, choosing the right valve can significantly impact not only water conservation efforts but also the overall functionality of industrial processes. As industries continue to prioritize resource management in response to increasing regulatory pressures and environmental concerns, understanding how to select the ideal Water Regulator Valve becomes paramount for achieving optimal performance and compliance.

Understanding the Importance of Water Regulator Valves in Industrial Applications

Water regulator valves are critical components in industrial applications, ensuring that water pressure is controlled and maintained at optimal levels. According to a report by Market Research Future, the global water regulation valve market is expected to grow at a CAGR of approximately 5% between 2021 and 2026, highlighting the increasing dependency of industrial sectors on effective water management solutions. These valves not only regulate pressure but also prevent potential damage to machinery caused by water hammer and fluctuations in supply pressure.

Water regulator valves are critical components in industrial applications, ensuring that water pressure is controlled and maintained at optimal levels. According to a report by Market Research Future, the global water regulation valve market is expected to grow at a CAGR of approximately 5% between 2021 and 2026, highlighting the increasing dependency of industrial sectors on effective water management solutions. These valves not only regulate pressure but also prevent potential damage to machinery caused by water hammer and fluctuations in supply pressure.

Furthermore, the American Society of Mechanical Engineers emphasizes that correctly calibrated water regulator valves are essential for maintaining system efficiency and preventing costly downtimes. In industries such as manufacturing and chemicals, where precise water flow is vital for processes like cooling and mixing, improper regulation can lead to serious operational issues.

Case studies indicate that companies that have invested in advanced water regulation systems have seen a reduction in water wastage by up to 30%, demonstrating both economic and environmental benefits. Hence, understanding the functionality and selection of the right water regulator valve is paramount for any industrial operation looking to enhance productivity and sustainability.

Key Factors to Consider When Selecting a Water Regulator Valve

When selecting the right water regulator valve for your industrial needs, several key factors must be considered to ensure optimal performance and longevity. First, understanding the specific application is crucial. Different industries—such as agriculture, manufacturing, and water treatment—have unique requirements. Evaluating the pressure level, flow rate, and temperature range of the water system will help you choose a valve that can handle those specific conditions without risk of failure.

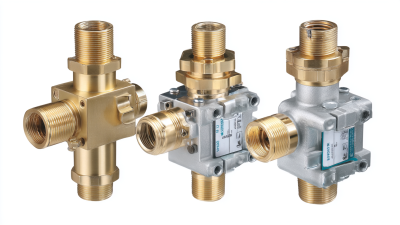

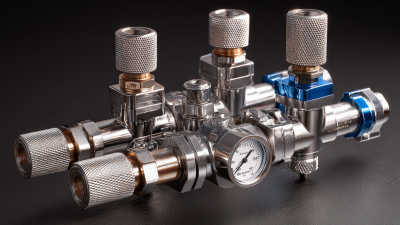

Another important consideration is the material composition of the valve. Valves made from materials like brass, stainless steel, or plastic will vary significantly in durability and resistance to corrosion, depending on the water characteristics and environmental conditions they will face. Additionally, ensure that the valve meets industry standards and certifications for safety and reliability. Finally, consider the ease of installation and maintenance, as this can impact downtime and operational efficiency in your facility. Selecting a valve that aligns with these key factors will contribute significantly to the overall performance of your water management system.

Key Factors for Choosing the Right Water Regulator Valve

Different Types of Water Regulator Valves and Their Specific Benefits

When selecting a water regulator valve for industrial applications, it's essential to understand the specific types available and their unique benefits. Generally, water regulator valves can be categorized into

pressure-reducing valves,

float valves, and

solenoid valves.

For instance, pressure-reducing valves are designed to maintain a constant downstream pressure regardless of fluctuations in the supply pressure. According to the

American Society of Mechanical Engineers (ASME), implementing these valves can reduce water usage by up to 25%, making them ideal for industries looking to enhance efficiency and lower operational costs.

Float valves, on the other hand, are crucial for maintaining water levels in tanks and reservoirs. They function automatically, allowing for continuous water flow without the risk of overflow. Industry reports indicate that utilizing float valves can improve water management systems by over 30%, significantly reducing wastage.

Lastly, solenoid valves, which are electrically operated, offer precise control over water flow in automated systems. Data from the

International Water Association (IWA) shows that industries utilizing solenoid valves can achieve up to 40% savings in water consumption due to their capability to regulate flow dynamically based on real-time demands. Understanding these options allows businesses to tailor their water regulation strategies effectively.

How Size and Pressure Ratings Affect Water Regulator Valve Performance

When selecting a water regulator valve for industrial applications, understanding the impact of size and pressure ratings is critical. A valve's size directly influences its flow capacity, making it essential to choose a valve that matches your pipeline dimensions. According to a recent industry report from the Fluid Control Association, improper valve sizing can result in flow restrictions, causing both operational inefficiencies and increased energy consumption—potentially exhausting up to 30% more energy in specific setups.

Pressure ratings are equally significant, as they determine a valve's ability to withstand operational conditions. Industrial environments often fluctuate between various pressures, and selecting a valve with an appropriate pressure rating ensures reliability and longevity. The American Society of Mechanical Engineers (ASME) suggests that mismatched pressure ratings can lead to catastrophic failures, resulting in costly downtime.

**Tip:** Always cross-reference the manufacturer’s specifications with industry standards to ensure optimal performance.

Consider consulting with an engineering professional when determining the requirements for size and pressure, as they can provide expertise tailored to your specific operations.

**Tip:** Utilizing simulation software can also help analyze the performance of different valves under varying conditions, ultimately aiding in achieving the best choice for your industrial needs.

How to Choose the Right Water Regulator Valve for Your Industrial Needs

| Regulator Type | Size (inches) | Pressure Rating (PSI) | Flow Capacity (GPM) | Material |

|---|---|---|---|---|

| Diaphragm Regulator | 2 | 150 | 20 | Brass |

| Electronic Regulator | 3 | 300 | 40 | Stainless Steel |

| Pressure Reducing Valve | 4 | 200 | 30 | PVC |

| Float Valve | 1.5 | 100 | 15 | Bronze |

Maintenance Tips for Prolonging the Life of Your Water Regulator Valve

When it comes to industrial applications, maintaining the functionality of your water regulator valve is crucial for ensuring efficient operations. Regular maintenance not only prolongs the life of the valve but also prevents costly downtime. Start by frequently inspecting the valve for any signs of leakage, corrosion, or buildup of debris that could affect performance.

Clean external components regularly, as dirt can lead to malfunction, and ensure that the valve’s inlet and outlet ports are free from obstructions.

In addition to visual inspections, it’s essential to check and adjust the pressure settings according to the manufacturer's specifications. Over time, pressure settings can drift, leading to inefficient system performance. Lubricate moving parts as recommended, using the appropriate grease or oil to ensure smooth operation. Lastly, keep a routine schedule for comprehensive maintenance checks, including testing the valve’s responsiveness and overall function, to detect issues before they escalate. By following these tips, you can enhance the lifespan of your water regulator valve and maintain optimal performance in your industrial operations.

Related Posts

-

5 Essential Tips for Choosing Your Water Pressure Regulator Valve

-

10 Reasons Pressure Regulator Valve is Essential for Industrial Applications

-

Understanding Industry Standards for Best Slide Gate Valve Manufacturing Processes

-

Mastering High Pressure Regulation: A Step-by-Step Guide to Choosing the Best Regulator

-

Top 5 Innovative Applications of the Best High Pressure Regulators in Various Industries

-

Identifying Common Issues with Gas Regulators: Ensuring Safety and Efficiency in Your System