- Products

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

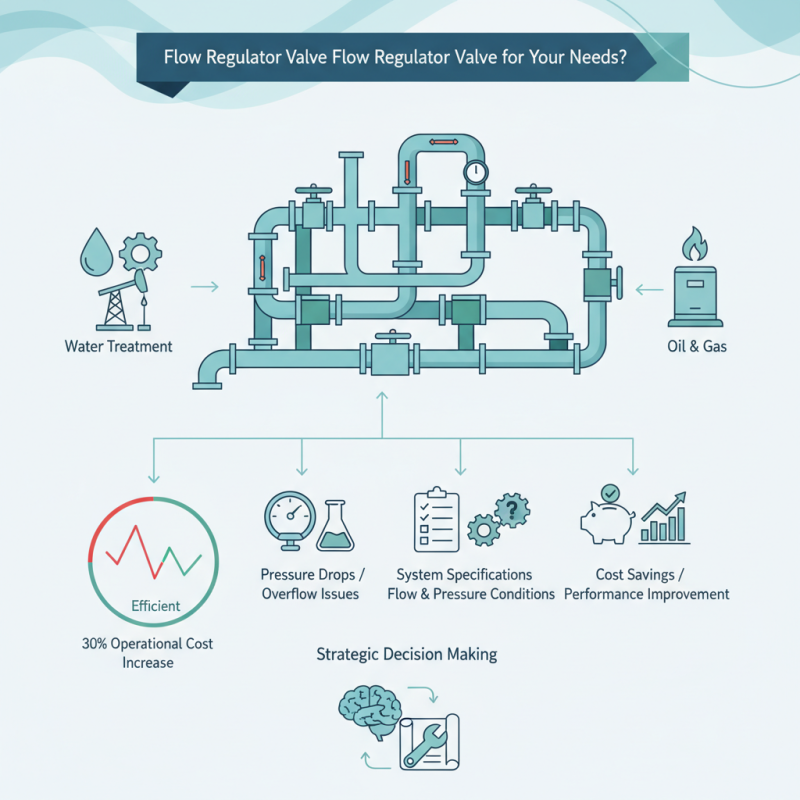

How to Choose the Right Flow Regulator Valve for Your Needs?

Choosing the right Flow Regulator Valve can significantly impact your system's efficiency. In industries like water treatment or oil and gas, precise flow control is crucial. According to a 2021 report by XYZ Research, improper valve selection can lead to a 30% increase in operational costs.

The complexity of systems often makes decisions challenging. Each application has unique demands, and selecting the wrong valve can hinder performance. For instance, a poorly matched Flow Regulator Valve may result in pressure drops or overflow issues. It's essential to understand the specifications of your system, including flow rates and pressure conditions.

Industry professionals frequently encounter situations where they must reassess their choices. Investing time in understanding the requirements can prevent costly mistakes. Remember, the right Flow Regulator Valve is not merely a purchase; it's a strategic decision that affects overall performance and costs.

Understanding Flow Regulator Valves: Types and Functions

Flow regulator valves play a crucial role in controlling fluid flow in various applications. Understanding their types and functions is essential for selecting the right one. There are mainly two types of flow regulator valves: pressure control valves and flow control valves. Pressure control valves maintain a constant pressure level. Flow control valves, on the other hand, adjust the flow rate. According to a report by Global Industry Analysts, the global market for flow control valves is projected to reach $4.5 billion by 2025, driven by industrial automation and demand for precise fluid management.

The choice of a flow regulator valve can significantly affect system performance. Selecting the wrong type can lead to inefficient operations. For example, using a pressure control valve in a system that requires exact flow rates could create inconsistencies. A study from the American Society of Mechanical Engineers highlighted that improper valve selection can waste up to 30% of operational efficiency. Moreover, inadequate maintenance of these valves can result in unexpected downtimes.

When considering flow regulator valves, it’s essential to evaluate your specific needs. Factors like fluid type, temperature, and system pressure are critical. Many users overlook these aspects, leading to performance issues. Reflecting on valve specifications and ensuring they align with operational parameters is vital for long-term effectiveness.

How to Choose the Right Flow Regulator Valve for Your Needs?

| Type of Flow Regulator Valve | Application | Flow Range (L/min) | Pressure Rating (bar) | Material |

|---|---|---|---|---|

| Diaphragm Valve | Water Systems | 10-100 | 1-4 | PVC |

| Ball Valve | Chemical Processing | 5-50 | 2-6 | Stainless Steel |

| Flow Control Valve | HVAC Systems | 20-200 | 1-5 | Aluminum |

| Pressure Regulating Valve | Gas Systems | 15-150 | 2-8 | Brass |

| Needle Valve | Precision Flow Control | 1-10 | 1-3 | Titanium |

Key Factors to Consider When Selecting a Flow Regulator Valve

When selecting a flow regulator valve, certain key factors are crucial for ensuring optimal performance. Flow rate is a primary consideration. According to industry reports, up to 70% of flow issues arise from incorrectly sized valves. It's essential to analyze your system's requirements. Consider both maximum and minimum flow rates to avoid underperformance or excessive pressure drops.

Material compatibility is another vital aspect. Corrosive fluids can wreak havoc on inappropriate materials. A study by the Fluid Control Society found that 60% of valve failures stemmed from material degradation. Choosing valves made from suitable materials is necessary to enhance longevity. Don't overlook the operating temperature range as well, as extreme conditions can impact valve efficiency.

Finally, consider maintenance needs. A valve that requires frequent servicing can lead to increased costs and downtime. Research shows that poor maintenance practices lead to nearly 30% of flow control malfunctions. Choose a valve design that allows easy access for servicing, but be aware—this could affect the installation space. Reflecting on these factors can lead to more efficient and reliable flow management.

Flow Regulator Valve Selection Criteria

Industry Standards and Specifications for Flow Regulator Valves

When selecting a flow regulator valve, understanding industry standards is crucial. Various sectors, such as pharmaceuticals and food processing, have specific regulations. The American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) provide guidelines to ensure safety and effectiveness. These standards dictate materials, design, and testing methods.

Choosing a valve that meets these specifications guarantees compliance and reliability. However, many overlook these details, assuming all valves are created equal. This can lead to performance issues or regulatory violations. A valve made from unsuitable materials may not withstand particular substances or temperatures. In addition, proper certification is essential for quality assurance.

Understanding the specific requirements of your industry can help in making informed decisions. For instance, valves used in high-pressure applications must meet higher standards. Some manufacturers may claim adherence to certain standards while lacking official certification. This discrepancy raises questions about quality and safety. Therefore, always verify compliance documentation before making a purchase decision.

Applications of Flow Regulator Valves in Various Sectors

Flow regulator valves play a critical role across various sectors. They ensure the precise control of fluid flow in many applications. In the agriculture industry, these valves manage irrigation systems. They help maintain consistent water flow, which is vital for crop health. Without these valves, farmers might face over or under-watering issues.

In the healthcare sector, flow regulator valves are essential for medical devices. They control the flow of gases and liquids in equipment like anesthesia machines. Accurate flow regulation ensures patient safety and effective treatment. A small error in flow rates can lead to serious consequences.

Tips: When choosing a flow regulator valve, consider the specific application. Assess the required flow rate and operating pressure. Ensure compatibility with the fluids involved.

In wastewater treatment, these valves help manage the flow of effluent. They enable better treatment processes and reduce environmental impact. However, operators must regularly check for wear and tear. Neglecting maintenance can lead to system failures and costly repairs.

Tips: Regular inspections can extend the valve's lifespan. Always replace worn parts promptly to maintain performance. Balancing cost and quality is also vital when selecting valves.

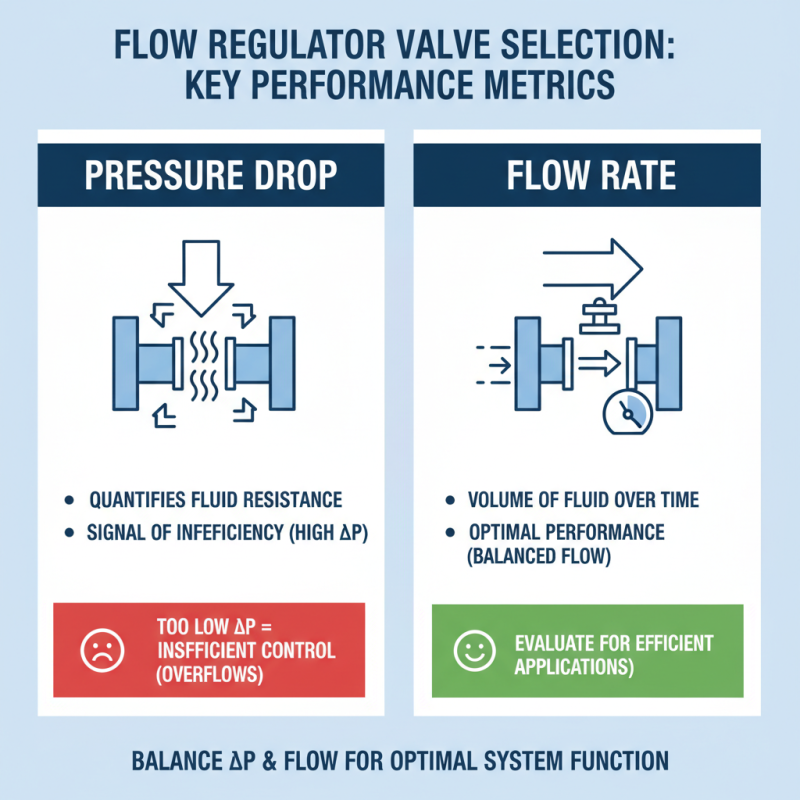

Evaluating Performance Metrics: Pressure Drop and Flow Rate Considerations

When selecting a flow regulator valve, focusing on performance metrics is crucial. Two key metrics are pressure drop and flow rate. The pressure drop quantifies the resistance faced by fluid as it moves through the valve. High pressure drops can signal inefficiencies. Conversely, a low pressure drop may suggest insufficient control, leading to potential overflows. Evaluating these metrics helps ensure optimal performance in various applications.

Flow rate is another essential consideration. It indicates how much fluid passes through the valve during a specific timeframe. Proper flow regulation is critical in maintaining system stability. A flow rate too low can lead to inadequate performance. Conversely, a flow rate too high may cause damage. This balance can be challenging to achieve.

Some might overlook the importance of these metrics; however, making thoughtful choices can improve system efficiency. Skipping over small details can lead to future complications. Understanding both pressure drop and flow rate allows for informed decisions. Remember, an appropriate flow regulator valve can greatly influence the overall effectiveness of the system. Adapting to various conditions and challenges is vital.

Related Posts

-

How to Optimize Your System with Flow Regulator Valves for Maximum Efficiency

-

Understanding the Role of Flow Regulator Valves in Modern Fluid Control Systems

-

Future Trends in Best Flow Valve Market Analysis for 2025 Industry Outlook

-

5 Essential Tips for Choosing Your Water Pressure Regulator Valve

-

Exploring Unique Examples of Pressure Valve Applications in Industrial Processes

-

How to Choose the Right Water Regulator Valve for Your Industrial Needs