- Products

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

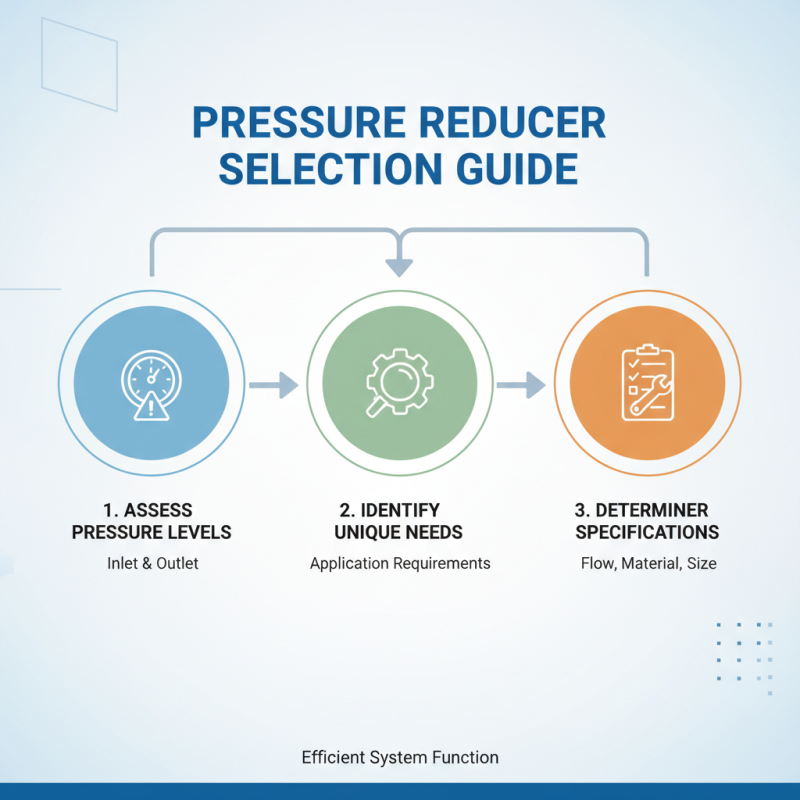

How to Choose the Right Pressure Reducer for Your Needs

Choosing the right pressure reducer for your specific needs is crucial for ensuring efficiency, safety, and optimal performance in various applications. A pressure reducer serves as a vital component in managing and regulating the pressure of gases or liquids within a system, thereby protecting equipment, enhancing functionality, and prolonging lifespan. With a myriad of options available in the market, understanding the fundamental aspects of pressure reducers becomes imperative for making an informed decision.

When considering a pressure reducer, one must take into account various factors such as the type of media being controlled, the desired pressure range, flow rate requirements, and compatibility with existing systems. Each application may present unique challenges and requirements, making it essential to conduct thorough research and assessment prior to selecting the most suitable pressure reducer. By carefully evaluating these elements, users can not only optimize system performance but also prevent common issues associated with improper pressure regulation, such as leaks, pressure fluctuations, and equipment damage. Ultimately, investing time and effort in choosing the right pressure reducer will lead to better overall outcomes and enhanced operational efficiency.

Understanding Pressure Reducers and Their Applications

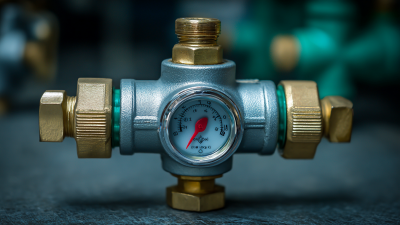

Pressure reducers are essential components in various applications, ensuring that gas or liquid pressure remains within safe and functional limits. Understanding how these devices work and their specific applications can help you select the right model for your needs. Pressure reducers are commonly used in industrial settings, HVAC systems, and even medical equipment, where consistent pressure is crucial for performance and safety. By managing pressure effectively, they prevent equipment damage, enhance efficiency, and improve overall system reliability.

When choosing a pressure reducer, it’s vital to consider several factors. The first is the pressure range required for your application, as different reducers are designed for varying pressures. Additionally, you should assess the media type—whether gas or liquid—as this will influence the material and design of the pressure reducer. Another key aspect is the flow rate; ensure that the reducer can accommodate the volume of fluid or gas required by your system without causing bottlenecks.

**Tips:**

- Always verify the maximum inlet pressure to ensure the reducer’s compatibility with your existing systems.

- Consider the environment where the reducer will be installed, as factors like temperature and humidity can affect its performance.

- Regular maintenance checks can prolong the life of a pressure reducer, preventing unexpected malfunctions and ensuring continuous operation.

Identifying Your Specific Needs and Requirements

When selecting the right pressure reducer for your specific applications, it is crucial to identify your unique needs and requirements. Start by assessing the pressure levels you are working with. Consider the inlet and outlet pressures necessary for your system to function efficiently. This initial analysis will guide you in determining the specifications needed for an effective pressure reducer.

Next, think about the type of media that will flow through the reducer. Different media can create varying demands on the reducer's material and design. For example, gases may require different considerations than liquids in terms of pressure sensitivity and flow rate. Additionally, evaluate the volume of flow your application necessitates to ensure that the pressure reducer can maintain stable performance under varying conditions.

**Tips:** When choosing a pressure reducer, always refer to the manufacturer's guidelines for compatibility with your specific application. Conducting pressure tests in controlled conditions can also provide valuable insights into performance and reliability. Lastly, don't overlook the importance of installation and maintenance. Proper setup can significantly influence the effectiveness of your chosen equipment.

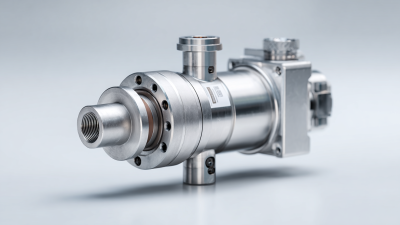

Evaluating Different Types of Pressure Reducers

When selecting the right pressure reducer, it is essential to understand the various types available on the market to ensure compatibility with your specific application. Pressure reducers are primarily categorized into mechanical, electronic, and integrated systems. Mechanical reducers typically provide a simple, cost-effective solution for applications with steady flow rates and low variations in pressure. According to a recent industry report by the International Society of Automation, mechanical valves account for approximately 40% of the total market share due to their reliability and ease of installation.

On the other hand, electronic pressure reducers offer advanced features such as real-time monitoring and precise pressure control, making them suitable for applications requiring high accuracy. A study by the Industrial Automation Association indicated that the electronic pressure regulator segment is projected to grow at a CAGR of 5.8% from 2022 to 2027, driven by increased automation in manufacturing processes. Additionally, integrated systems, which combine pressure regulation with other functions like flow measurement, are gaining popularity in complex applications. Their ability to streamline operations and reduce the need for multiple devices is reflected in a 2022 report by the Engineering & Technology Corporation, which noted that integrated solutions are becoming a preferred choice for industries looking to optimize efficiency and reduce space constraints.

Key Features to Consider When Choosing a Pressure Reducer

When choosing the right pressure reducer for your needs, several key features should be taken into account to ensure optimal performance and safety. First and foremost, it’s essential to consider the pressure range required for your specific application. Different pressure reducers are designed to handle various pressure levels, so identifying the maximum and minimum pressures you’ll be working with will help narrow down your options effectively.

Another critical feature to examine is the flow rate. The pressure reducer should be capable of providing an adequate flow while maintaining a stable output pressure. Look for products that specify their maximum and minimum flow capacities, as this will ensure that your system operates efficiently without any pressure spikes that could damage your equipment.

Tips: Always check the materials used in the construction of the pressure reducer. Certain materials are more resistant to corrosion or can handle higher temperatures, depending on your environment. Additionally, consider the connectors and fittings; they should match your existing system to avoid any leaks or inefficiencies. Lastly, don’t overlook the ease of maintenance; a reducer with accessible components will save you time and effort in the long run.

Installation and Maintenance Tips for Pressure Reducers

When installing a pressure reducer, it is crucial to follow a few key steps to ensure it operates effectively. First, make sure to select the appropriate location for the reducer, ideally close to the pressure source to minimize pressure drop over longer distances. Use Teflon tape or a similar sealing compound on threaded connections to prevent leaks. Additionally, it's essential to check the alignment of the reducer with the inlet and outlet piping. A misalignment can cause unnecessary wear and tear.

Maintenance is another vital aspect of ensuring the longevity and performance of your pressure reducer. Regularly inspect the device for signs of wear, leaks, or corrosion, particularly at the seals and joints. It’s recommended to clean the inlet and outlet filters if they are fitted, as dirt and debris can impede performance. Periodic testing of the pressure settings will confirm that the reducer is functioning within the desired parameters.

Tips: When adjusting the pressure settings, make small adjustments and allow the system to stabilize before making further changes. This technique helps in preventing sudden pressure fluctuations that could strain your system. Lastly, consult the manufacturer's guidelines for specific maintenance recommendations tailored to your model; these instructions often include crucial information that may influence the overall efficiency and safety of the reducers.

Related Posts

-

Emerging Trends in Back Pressure Valve Technology by 2025 and Their Key Advantages for Global Buyers

-

Mastering High Pressure Regulation: A Step-by-Step Guide to Choosing the Best Regulator

-

Understanding the Essential Role of Pressure Regulator Valves in Industrial Applications

-

Understanding the Role of Gas Regulators in Safe Domestic and Industrial Applications

-

Exploring Back Pressure Valve Innovations in the Context of China's 138th Canton Fair 2025 Industry Trends

-

Maximizing Efficiency: The Essential Guide to Choosing the Right Water Regulator Valve for Your Needs