- Products

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

Top Reasons Why a Pressure Regulator is Essential for Your Gas or Liquid System

In industrial and commercial applications, maintaining the integrity and efficiency of gas or liquid systems is paramount. A Pressure Regulator plays a critical role in this regard, ensuring that the pressure within these systems remains within safe and operational limits. According to a report from the National Institute of Standards and Technology (NIST), improper pressure regulation can lead to equipment failures, safety hazards, and costly downtime, affecting productivity and potentially leading to significant financial losses.

Moreover, the global market for pressure regulators is projected to reach $5 billion by 2025, reflecting the increasing demand for efficient pressure control solutions across various sectors, including manufacturing, chemical processing, and oil and gas. Inadequate pressure management can result in operational inefficiencies, with studies indicating that up to 30% of energy costs in industrial processes can be attributed to poor pressure regulation practices. Thus, investing in high-quality Pressure Regulators not only enhances system performance and safety but also contributes to overall cost-efficiency and resource optimization in fluid management systems.

Importance of Pressure Regulation in Gas and Liquid Systems

Pressure regulation plays a vital role in the efficient operation of gas and liquid systems. By maintaining a consistent pressure, these regulators prevent fluctuations that can lead to equipment malfunction, reduce efficiency, and cause potential safety hazards. In gas systems, for instance, high pressure can cause leaks or explosions, while in liquid systems, excessive pressure might result in pipe bursts or compromised integrity of the materials in use.

Thus, ensuring optimal pressure not only enhances system performance but also guarantees compliance with safety standards.

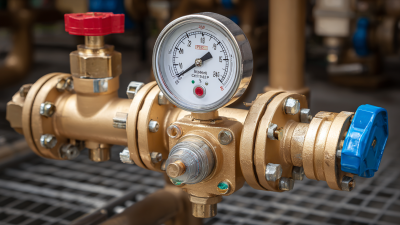

Tips for effective pressure regulation include regularly inspecting your pressure regulator for wear and tear, as this can affect its performance over time. Ensure that the regulator is appropriately sized for your system; an undersized regulator may struggle to maintain consistent pressure, while an oversized one can lead to inefficiencies. Additionally, consider installing pressure gauges to monitor real-time pressure levels, which can provide insights into whether your system is operating within the desired parameters.

Maintaining proper pressure is not just about performance; it is also about extending the lifespan of your equipment. Regular maintenance and timely adjustments can save costs associated with repairs and replacements. By prioritizing pressure regulation, you can optimize your gas or liquid system’s efficiency and safety, creating a more reliable operation overall.

Understanding Pressure Regulators: Function and Mechanism

Pressure regulators play a critical role in managing the pressure of gases and liquids within a system, ensuring that they operate safely and efficiently. These devices adjust the downstream pressure to a desired level, regardless of fluctuations in upstream pressure, allowing for consistent and predictable performance. According to a report by MarketsandMarkets, the pressure regulator market is expected to grow significantly, reflecting its increasing importance across various industries, including oil and gas, healthcare, and manufacturing.

The mechanics of a pressure regulator are based on a simple yet effective principle: they utilize a control element, which responds to changes in output pressure to modulate the flow of fluids. This feedback loop is essential for maintaining the desired setpoint, thereby preventing pressure surges that could damage equipment or lead to hazardous situations. Data from the National Fire Protection Association indicates that over 20% of industrial accidents are linked to inadequate pressure control, underscoring the necessity of reliable pressure regulation in maintaining safety and operational integrity.

Furthermore, pressure regulators are integral to enhancing the efficiency of processes. By stabilizing pressure variations, they contribute to optimized energy consumption and reduced operational costs, leading to significant long-term savings for businesses. The U.S. Department of Energy reports that effective pressure management systems can reduce energy consumption in industrial applications by up to 15%, highlighting the economic and operational benefits of incorporating pressure regulators into gas and liquid systems.

Key Benefits of Using a Pressure Regulator in Systems

Pressure regulators play a critical role in both gas and liquid systems, ensuring stable and efficient operation. One of the key benefits of utilizing a pressure regulator is the enhancement of system safety. According to industry reports, improperly regulated pressure can lead to equipment failures and hazardous situations, with data indicating that nearly 30% of operational disruptions in industrial settings are linked to pressure irregularities. By maintaining optimal pressure levels, regulators prevent over-pressurization, significantly reducing the risk of equipment damage and associated operational downtimes.

Another advantage of pressure regulators is their contribution to system efficiency. By providing consistent pressure, these devices help optimize the performance of the entire system. Studies have shown that systems equipped with pressure regulators can operate up to 20% more efficiently compared to those without, as they minimize energy consumption and material waste. Additionally, precise control over pressure allows for better process optimization, enabling industries to achieve desired outcomes with less resource expenditure. This improved efficiency not only supports sustainability efforts but also leads to substantial cost savings over time, making pressure regulators an indispensable component of modern fluid handling systems.

Common Applications of Pressure Regulators in Industry

Pressure regulators play a vital role in various industrial applications, ensuring that gas or liquid systems operate smoothly and safely. In manufacturing processes, pressure regulators are essential in maintaining the desired pressure levels within equipment, which helps prevent equipment damage and allows for efficient operation. Industries such as pharmaceuticals and food processing rely on pressure regulators to maintain precise pressure settings, ensuring product quality and compliance with safety standards.

Another significant application of pressure regulators is in the energy sector, where they are utilized in both natural gas distribution and petrochemical processes. By regulating the pressure of gases, these devices help to safeguard pipelines and equipment from the dangers of overpressure. In the HVAC industry, pressure regulators are crucial for controlling refrigerant pressures, enhancing the efficiency of cooling and heating systems. Overall, the versatility of pressure regulators makes them indispensable across various industries, contributing to safety, efficiency, and performance optimization.

Top Reasons Why a Pressure Regulator is Essential for Your Gas or Liquid System

This chart illustrates the common applications of pressure regulators in various industries. Each segment represents the percentage of use in gas and liquid systems across different sectors.

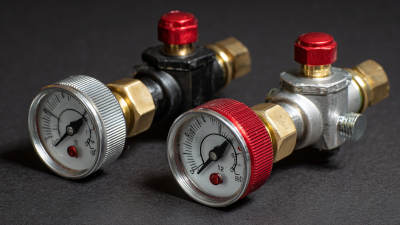

Selecting the Right Pressure Regulator for Your System Needs

When selecting the right pressure regulator for your gas or liquid system, understanding your system's specific needs is vital. A pressure regulator ensures that the pressure remains stable, preventing fluctuations that can lead to equipment damage or inefficient operation. Consider factors such as the operating pressure range, type of media being controlled, and flow requirements when making your choice. Different applications, from industrial processes to residential systems, may necessitate a unique approach to pressure regulation.

**Tips:** Always consult your system specifications before making a decision. Having detailed information about your anticipated pressure and flow requirements can help in selecting a regulator that matches your needs perfectly. Additionally, consider the materials of construction; they should be compatible with the fluids or gases you will be working with to ensure longevity and reliability.

Another important aspect is the size and installation requirements of the regulator. Ensure that the chosen device fits within your available space and is easily accessible for maintenance and adjustments. Proper installation is key to achieving optimal performance—follow guidelines to avoid complications down the line. Implementing a suitable pressure regulator not only enhances system reliability but also maximizes efficiency, ultimately leading to cost savings over time.

Related Posts

-

Mastering High Pressure Regulation: A Step-by-Step Guide to Choosing the Best Regulator

-

Top Strategies for Maximizing Efficiency with High Pressure Regulators

-

10 Reasons Pressure Regulator Valve is Essential for Industrial Applications

-

Understanding the Essential Role of Pressure Regulator Valves in Industrial Applications

-

How to Choose the Right Pressure Regulator for Your Industrial Needs

-

How to Choose the Right High Pressure Gas Regulator for Your Application