- Products

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

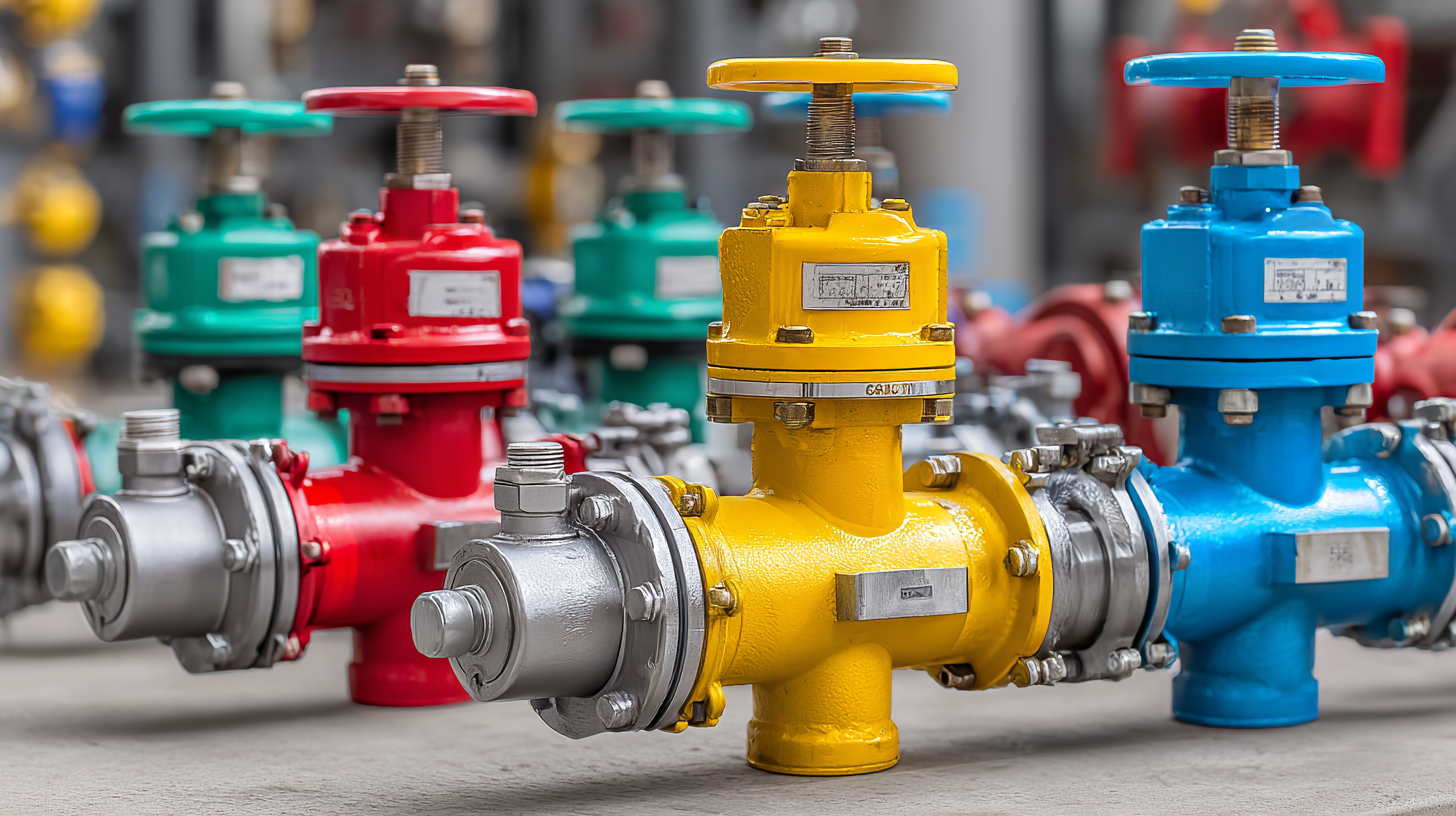

10 Essential Reasons to Choose the Best Gas Regulator Valve for Your Needs

In the world of gas distribution and utilization, the choice of a Gas Regulator Valve is critical for ensuring safety, efficiency, and reliability. According to a report by the Gas Technology Institute, improper regulation of gas pressure can lead to equipment failure, hazardous leaks, and even accidents, costing businesses thousands in damages and lost productivity. With the global gas regulator market expected to reach USD 6.1 billion by 2025, the importance of selecting the right valve has never been more pronounced. This essential component not only regulates flow and pressure but also adapts to varying demands, making it vital for applications across industries such as manufacturing, healthcare, and energy. Understanding the key factors in choosing the best Gas Regulator Valve can significantly impact performance and safety levels, fostering more sustainable operations and contributing to overall industry advancements.

Key Factors to Consider When Selecting a Gas Regulator Valve

When it comes to selecting a gas regulator valve, several key factors come into play to ensure you choose the right one for your specific needs. First and foremost, it’s crucial to evaluate the flow capacity required for your application. Different systems demand varying amounts of gas flow; hence, selecting a regulator with the appropriate capacity will optimize performance and safety. Consideration of the inlet and outlet pressure ratings is equally important, as these parameters define the regulator’s efficiency and operational reliability under your specific conditions.

Material compatibility should also be on your checklist. Different gases and operating environments can lead to deterioration or failure of inferior materials. Therefore, understanding the type of gases you'll be using and selecting a regulator made of suitable materials will enhance durability and minimize risks. Additionally, pay attention to features such as pressure gauges, adjustability, and safety shut-off mechanisms, as these can significantly contribute to ease of use and safety in managing your gas supply. Ultimately, thorough consideration of these factors will lead you to the best gas regulator valve for your needs.

Comparative Analysis of Leading Gas Regulator Valve Brands in 2025

When it comes to selecting a gas regulator valve, understanding the differences between leading brands in 2025 is crucial for both safety and efficiency. Brands like Blustar, GasGuard, and FlameSafe have emerged as frontrunners, each offering unique features tailored to various applications. Blustar is renowned for its durable build and precision control, making it an excellent choice for high-performance requirements. In contrast, GasGuard focuses on user-friendly designs and advanced safety mechanisms, ideal for residential settings. FlameSafe has carved its niche with robust valves that cater to the industrial sector, ensuring reliable operation even under extreme conditions.

A comparative analysis of these brands reveals that while Blustar excels in high-pressure environments, GasGuard leads in consumer safety and ease of use. FlameSafe, on the other hand, offers versatility for commercial users who demand both reliability and adaptability. Each brand's commitment to quality demonstrates the importance of selecting a gas regulator valve that not only meets your specific needs but also adheres to safety standards. By investing time in evaluating these options, consumers can make informed decisions that enhance their overall gas management systems.

The Importance of Safety Features in Gas Regulator Valve Selection

When selecting a gas regulator valve, prioritizing safety features is paramount. A top-quality gas regulator valve not only ensures effective pressure regulation but also safeguards against potential hazards. Look for valves equipped with pressure relief mechanisms, which can release excess pressure that may accumulate, thereby preventing possible explosions or leaks.

Tips for selection: Always check for certifications from recognized safety organizations, as these indicate adherence to essential safety standards. Additionally, consider valves with built-in gauges that provide real-time pressure readings, allowing users to monitor gas supply conditions continuously.

Another important feature to consider is the durability of the materials used in the valve construction. Opt for regulators made from robust materials that can withstand varying environmental conditions, reducing the risk of wear and tear. A well-constructed valve will not only enhance safety but also extend the service life of your gas system.

Tips for maintenance: Regularly inspect your gas regulator valve for signs of wear or damage. Clean any debris and ensure seals are intact to maintain optimal operation and safety.

10 Essential Reasons to Choose the Best Gas Regulator Valve for Your Needs

This chart illustrates the importance of various safety features in gas regulator valve selection based on user concerns and preferences.

Cost vs. Quality: Finding the Best Value in Gas Regulator Valves

When selecting a gas regulator valve, the balance between cost and quality is a critical consideration for consumers. According to a report by Markets and Markets, the global gas regulator market is expected to reach USD 2.69 billion by 2026, growing at a CAGR of 5.1%. This indicates a robust demand for regulators, which underlines the importance of investing in quality products that can minimize operational issues and maximize safety. A cheap gas regulator may save upfront costs, but it can lead to significant expenses down the line due to operational failures or safety hazards.

Furthermore, choosing a gas regulator with high durability and reliability can greatly reduce maintenance costs. A study published in the Journal of Industrial Safety revealed that up to 30% of gas-related accidents can be traced back to poor-quality valves and regulators. Such statistics highlight the need for consumers to prioritize quality over initial price. Ultimately, finding the best value means selecting a gas regulator that not only fits within your budget but also meets rigorous safety standards and performance benchmarks, ensuring long-term savings and peace of mind.

10 Essential Reasons to Choose the Best Gas Regulator Valve for Your Needs - Cost vs. Quality: Finding the Best Value in Gas Regulator Valves

| Feature | Importance | Cost Range (USD) | Quality Rating (1-5) |

|---|---|---|---|

| Pressure Control | Ensures safe operation | 50 - 150 | 5 |

| Material Durability | Affects lifespan | 60 - 200 | 4 |

| Flow Rate | Performance efficiency | 40 - 120 | 5 |

| Temperature Range | Versatility in use | 50 - 180 | 4 |

| Regulator Type | Compatibility with systems | 30 - 100 | 5 |

| Ease of Maintenance | Cost-effectiveness over time | 20 - 80 | 4 |

| Safety Features | Prevents accidents | 70 - 250 | 5 |

| Size and Portability | Convenience for transport | 25 - 90 | 4 |

| Warranty | Manufacturer support | 0 - 50 | 5 |

| Certification | Regulatory compliance | 0 - 100 | 5 |

Future Trends in Gas Regulation Technology: What to Expect in 2025

As we look toward the future of gas regulation technology, several trends are shaping the landscape for 2025 and beyond. According to a recent report by the International Energy Agency (IEA), the global demand for natural gas is projected to increase by 1.5% annually, driving the need for more efficient and reliable gas regulation systems. Innovations such as smart regulators, which utilize IoT technology for real-time monitoring and adjustments, will likely become mainstream, allowing operators to enhance safety and efficiency while reducing operational costs.

Moreover, environmental regulations are pushing manufacturers towards developing eco-friendly gas regulation solutions. The Global Gas Regulation Market report suggests that by 2025, over 30% of gas regulators will incorporate advanced materials that minimize leakage and emissions. Coupled with advancements in AI and machine learning, these technologies will not only improve the accuracy of gas flow but also enable predictive maintenance, significantly reducing downtime. Stakeholders in the gas industry must prepare for a shift towards more sustainable practices while ensuring they adopt cutting-edge technology to meet the growing demands of the market.