- Products

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

Understanding the Essential Role of Pressure Regulator Valves in Industrial Applications

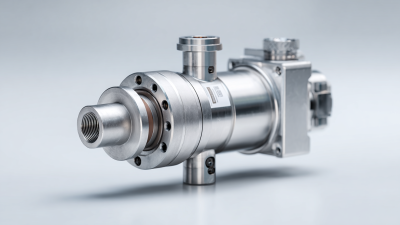

In the world of industrial applications, the efficiency and safety of systems heavily depend on the precise control of pressure, which is where the Pressure Regulator Valve plays a crucial role. These valves are designed to maintain a constant output pressure despite variations in input pressure, ensuring that equipment operates smoothly and safely.

As industries continue to evolve and adopt more advanced technologies, the importance of understanding how Pressure Regulator Valves function becomes paramount. In this blog, we will delve into the essential responsibilities of these valves, explore various applications across different sectors, and provide actionable tips on selecting, maintaining, and optimizing their use in your operations.

Whether you're a seasoned professional or a newcomer to the field, this guide aims to enhance your knowledge and improve your operational efficiency through a deeper understanding of Pressure Regulator Valves.

The Importance of Pressure Regulator Valves in Industrial Settings

In industrial settings, pressure regulator valves play a crucial role in maintaining optimal pressure levels within systems. These valves are essential for controlling the pressure of gases and liquids, ensuring that processes operate safely and efficiently. By adjusting the pressure coming from a supply source to a desired setpoint, pressure regulator valves help to prevent equipment damage, reduce the risk of leaks, and improve the overall performance of industrial operations.

The importance of pressure regulator valves extends beyond simple pressure control. They also contribute to the longevity of machinery and reduce energy consumption. In many applications, such as in manufacturing and processing plants, fluctuations in pressure can lead to inconsistent product quality and potential safety hazards. Pressure regulator valves provide stability, allowing operators to maintain precise control over their systems, which is vital in meeting regulatory standards and operational goals. Ultimately, the effective use of these valves is integral to achieving reliability and efficiency in industrial applications.

Top 5 Benefits of Using Pressure Regulator Valves in Operations

Pressure regulator valves (PRVs) play a crucial role in various industrial applications, and their benefits are especially pronounced in optimizing operations. One key advantage is that PRVs help maintain consistent pressure levels, which is essential for the efficient functioning of machinery and processes. According to a report by the National Fluid Power Association, systems that utilize PRVs can see efficiency improvements of up to 20%, as they mitigate pressure fluctuations that can lead to equipment failures or inconsistent output quality.

Pressure regulator valves (PRVs) play a crucial role in various industrial applications, and their benefits are especially pronounced in optimizing operations. One key advantage is that PRVs help maintain consistent pressure levels, which is essential for the efficient functioning of machinery and processes. According to a report by the National Fluid Power Association, systems that utilize PRVs can see efficiency improvements of up to 20%, as they mitigate pressure fluctuations that can lead to equipment failures or inconsistent output quality.

Another significant benefit of PRVs is their contribution to safety. By regulating the pressure within hydraulic or pneumatic systems, these valves prevent sudden pressure surges that could cause catastrophic failures. The Occupational Safety and Health Administration (OSHA) emphasizes that the use of pressure regulation equipment can reduce workplace incidents, as controlled environments contribute to safer operational parameters. Moreover, PRVs can enhance the lifespan of machinery by preventing excessive pressure-related wear, allowing companies to save on maintenance costs and downtime.

Lastly, the installation of pressure regulator valves can lead to considerable energy savings. A study by the U.S. Department of Energy found that implementing PRVs can reduce energy consumption in compressed air systems by as much as 30%. This not only lowers operational costs but also supports sustainability efforts within industries aiming to minimize their carbon footprint. Therefore, the integration of PRVs in industrial operations offers a blend of efficiency, safety, and cost-effectiveness, making them indispensable in modern applications.

7 Key Features to Look for in High-Quality Pressure Regulator Valves

When selecting high-quality pressure regulator valves for industrial applications, it’s crucial to consider several key features that ensure efficiency and reliability. Firstly, look for valves that offer precise pressure control. This capability is critical for maintaining consistent pressure levels, which can directly impact the performance of your systems. Additionally, check for a durable construction material that can withstand varying temperatures and harsh environmental conditions.

Another essential feature is the valve's response time. A fast response ensures that the pressure adjustments are immediate and effective, helping to prevent potential system failures. Furthermore, consider models that include easy-to-read pressure gauges and adjustment mechanisms, allowing for quick monitoring and adjustments as necessary.

Tip: Regular maintenance and inspection of pressure regulator valves can significantly extend their lifespan and optimize performance. Make it a habit to check for leaks and ensure that the valves are free from debris, as this can greatly affect their efficiency. Additionally, choose valves that offer easy accessibility for servicing, which can save time and resources in the long run.

Pressure Regulator Valves: Key Features and Their Importance

This bar chart illustrates the importance level of various key features to consider when selecting high-quality pressure regulator valves for industrial applications. Each feature is rated on a scale from 1 to 10, with higher values indicating greater importance.

The Impact of Pressure Regulation on Safety and Efficiency in Industries

Pressure regulator valves are a critical component in many industrial systems, ensuring that operations run smoothly and safely. The primary function of these valves is to maintain a consistent pressure level, which is vital for the proper functioning of equipment and processes. In industries such as manufacturing, oil and gas, and pharmaceuticals, fluctuations in pressure can lead to catastrophic failures, production downtime, and safety hazards. By regulating pressure, these valves prevent over-pressurization, which can cause equipment damage and lead to dangerous situations.

Moreover, effective pressure regulation directly impacts operational efficiency. By ensuring that systems operate within optimal pressure ranges, these valves help minimize energy consumption and waste, leading to reduced operational costs. For instance, in pneumatic and hydraulic systems, maintaining the right pressure levels can optimize the performance of machinery and enhance productivity. Additionally, proper pressure regulation contributes to the longevity of equipment, reducing maintenance needs and minimizing unplanned outages. In summary, the role of pressure regulator valves extends beyond basic functionality; they are essential for ensuring both safety and efficiency in industrial applications.

Understanding the Essential Role of Pressure Regulator Valves in Industrial Applications

| Industry | Application | Pressure Regulation Importance | Efficiency Impact | Safety Considerations |

|---|---|---|---|---|

| Oil & Gas | Natural Gas Distribution | Maintains consistent flow to consumers | Reduces energy costs | Prevents leaks and explosions |

| Pharmaceutical | Drug Manufacturing | Ensures precise dosing | Improves product quality | Reduces contamination risk |

| Food & Beverage | Carbonation Control | Maintains optimal carbonation levels | Enhances flavor consistency | Ensures consumer safety |

| Chemical Manufacturing | Process Control | Controls reaction conditions | Optimizes production rates | Prevents hazardous situations |

| Water Treatment | Distribution Systems | Ensures proper flow rates | Improves energy efficiency | Protects public health |

Choosing the Right Pressure Regulator Valve: 4 Essential Factors to Consider

When selecting a pressure regulator valve for industrial applications, there are several essential factors to consider to ensure optimal performance and safety. The first crucial element is the pressure range specification. It’s vital to choose a valve that can handle the operational pressure of your system effectively. An incorrectly specified pressure range can lead to over-regulation or under-regulation, causing potential equipment damage and safety hazards.

Another important factor is the type of media that will pass through the pressure regulator. Different materials are compatible with various gases and liquids. Ensuring that the valve material is resistant to corrosion or contamination from the specific media will enhance durability and reliability.

Additionally, consider the flow rate requirements of your application. A valve that can maintain the necessary flow rate while regulating pressure will significantly contribute to process efficiency. Lastly, the environmental conditions, such as temperature and humidity, should not be overlooked, as they can impact valve performance and lifespan. By carefully evaluating these factors, you can make a more informed decision when selecting the right pressure regulator valve for your industrial needs.

Related Posts

-

Emerging Trends in Back Pressure Valve Technology by 2025 and Their Key Advantages for Global Buyers

-

Mastering High Pressure Regulation: A Step-by-Step Guide to Choosing the Best Regulator

-

10 Reasons Pressure Regulator Valve is Essential for Industrial Applications

-

Unlocking Performance: Key Technical Specifications of the Best Back Pressure Valve for Global Buyers

-

Top Strategies for Maximizing Efficiency with High Pressure Regulators

-

Navigating Import and Export Certifications for the Best Gas Regulators in the Market