- Products

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

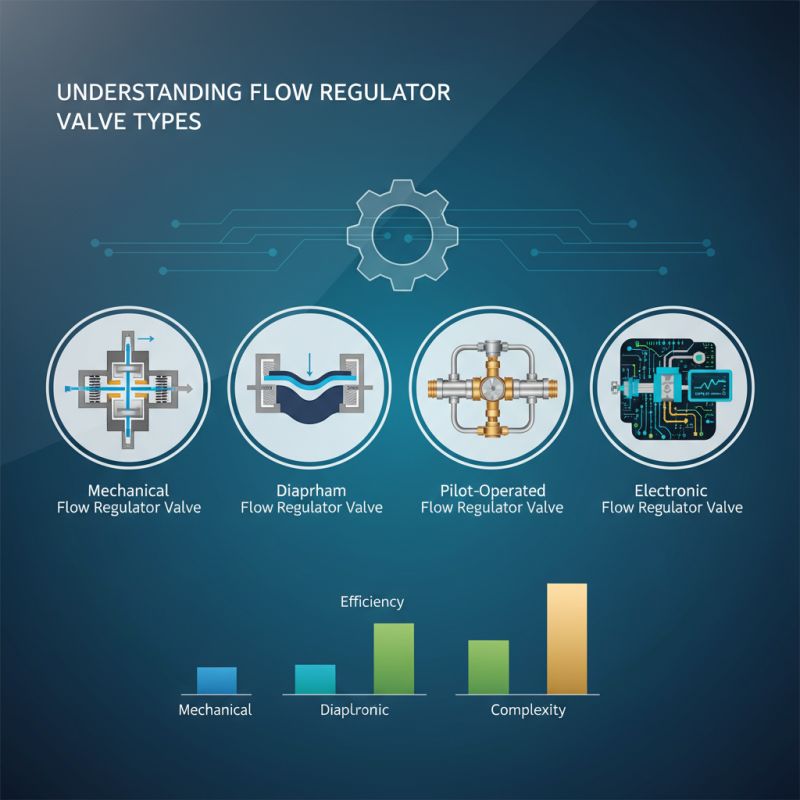

Understanding Flow Regulator Valve Types for Optimal Performance and Efficiency

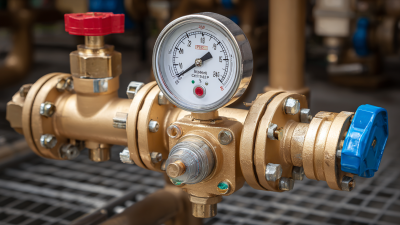

In the realm of fluid dynamics, the effective regulation of flow is essential for achieving optimal performance and efficiency across various applications. A key component in this process is the Flow Regulator Valve, which plays a crucial role in controlling the rate of fluid movement within a system. By maintaining desired flow rates, these valves not only contribute to system performance but also help in minimizing energy consumption and reducing wear and tear on machinery. Understanding the different types of Flow Regulator Valves is vital for engineers and designers looking to enhance system reliability and performance.

Different types of Flow Regulator Valves are designed to address specific flow characteristics and operational needs. From simple mechanical designs to advanced electronic controls, the selection of the appropriate valve type can significantly impact system efficiency and overall effectiveness. This introduction provides a foundation for exploring the various Flow Regulator Valve types, their operational principles, and the advantages they offer. By doing so, professionals can make informed decisions that lead to improved fluid management and optimized processes in their respective industries.

Types of Flow Regulator Valves: An Overview

Flow regulator valves play a crucial role in various industrial applications by maintaining consistent flow rates and pressures. Understanding the different types of flow regulator valves is essential for selecting the right valve to optimize system performance and efficiency. The most common types include pressure-regulating valves, flow-control valves, and pressure-compensated flow valves. Each type serves a unique function; for instance, pressure-regulating valves adjust the pressure in a system to prevent surges, while flow-control valves modulate the amount of fluid passing through them to ensure desired flow rates.

According to a report by the International Society of Automation, improper selection of flow regulation devices can lead to significant inefficiencies, costing industries an estimated 10% of their operational budgets annually. Furthermore, the market for flow regulation technologies is projected to grow at a CAGR of 5.2%, driven by increasing demand for efficient fluid control solutions across multiple sectors, including manufacturing, water treatment, and HVAC.

Understanding the technical specifications and applications of these valve types enables engineers and decision-makers to enhance system efficiency, reduce energy consumption, and minimize operational costs.

By evaluating parameters such as flow range, response time, and compatibility with various fluids, professionals can select the most appropriate valve design for their applications. A focused approach on valve types can lead to improved reliability in operations and contribute to sustainable practices by reducing waste and energy usage.

Key Characteristics of Different Flow Regulator Valve Types

Flow regulator valves are essential components in fluid control systems, influencing the efficiency and performance of various industrial processes. They come in several types, each with unique characteristics tailored to specific applications. The primary types include pressure-reducing valves, flow control valves, and pressure-regulating valves, each designed to maintain optimal flow rates while minimizing energy consumption.

Pressure-reducing valves work by automatically adjusting the flow rate based on downstream pressure changes, making them ideal for applications where consistent pressure is critical. According to a 2021 industry report by the Fluid Power Society, these valves can reduce energy costs by up to 30% when properly implemented in water distribution systems. On the other hand, flow control valves are designed to maintain a constant flow rate, regardless of pressure variations, proving invaluable in processes where precise flow measurements are necessary. Their performance is often quantified in terms of Cv rating, which indicates the flow capacity of the valve at a given pressure drop.

Pressure-regulating valves combine the functionalities of both pressure-reducing and flow control valves, offering a versatile solution for complex systems. Their design allows for better response to fluctuations in system demands, ensuring stability and efficiency. According to recent statistics from the American Society of Mechanical Engineers, the proper application of these valves can lead to a 15% improvement in system efficiency, highlighting their role in energy conservation and operational excellence. Understanding these key characteristics enables engineers to select the right type of flow regulator valve, ensuring optimal performance and enhanced efficiency across various sectors.

Applications of Flow Regulator Valves in Various Industries

Flow regulator valves play a crucial role across various industries, ensuring the efficient and precise control of fluid flow. In the agricultural sector, for example, these valves are essential for managing irrigation systems. By maintaining consistent water flow, they enhance crop yield while minimizing water wastage. This precision in regulating flow helps farmers optimize resource use and improve overall agricultural productivity, which is critical in addressing food security challenges.

In the manufacturing and chemical processing industries, flow regulator valves are vital for maintaining desired pressure and flow rates in production processes. They help in controlling the mixing of different substances, ensuring the quality and safety of products. The ability to adjust flow rates allows for flexibility and adaptation in manufacturing setups, facilitating innovation and efficiency. Additionally, in water treatment facilities, these valves are used to manage the flow of chemicals added to the water, ensuring that purification processes meet safety standards while optimizing chemical usage.

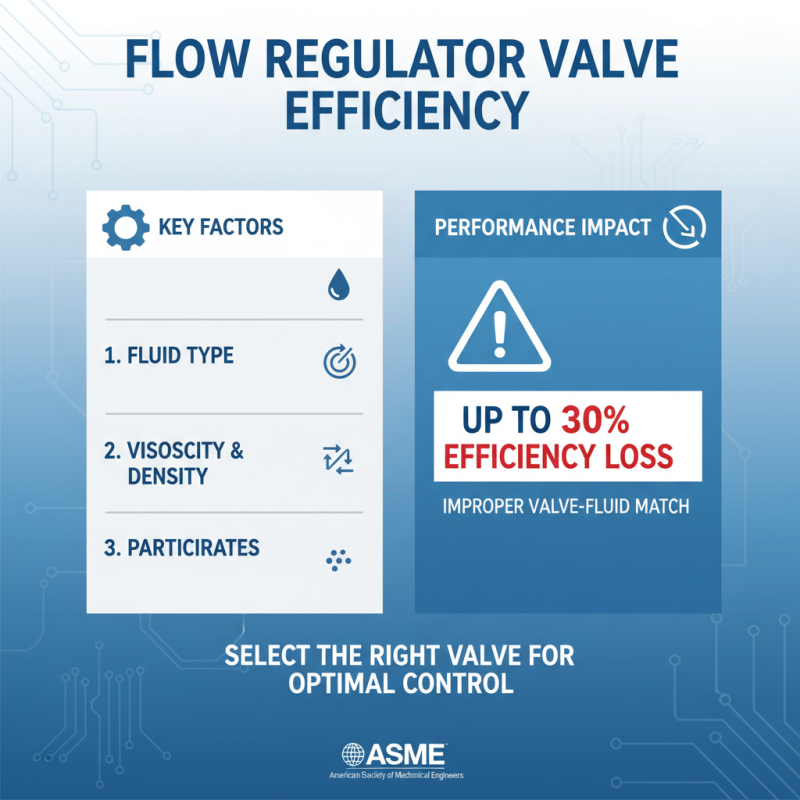

Factors Influencing the Performance of Flow Regulator Valves

When it comes to flow regulator valves, several key factors significantly affect their performance and efficiency in various applications. One of the primary considerations is the type of fluid being regulated. Viscosity, density, and the presence of particulates can all impact how effectively the valve controls flow. According to a recent report by the American Society of Mechanical Engineers (ASME), improper matching of a flow regulator valve to fluid properties can result in a performance drop of up to 30%. This underlines the importance of selecting the right valve based on the specific characteristics of the fluid in use.

Another critical factor is the pressure conditions under which the valve operates. Flow regulator valves may behave differently depending on variations in upstream and downstream pressures. A study from the International Journal of Fluid Mechanics highlighted that fluctuations in pressure can cause considerable instability in flow rates, leading to inefficiencies and potentially damaging system components. Therefore, ensuring that the valve is appropriately rated for the operational pressure range is vital for maintaining optimal performance.

Tips: When assessing flow regulator valves for specific applications, consider conducting tests to evaluate how various fluid characteristics affect valve response. Additionally, always consult with industry guidelines and leverage data from credible engineering publications to make informed decisions on valve selection, which can lead to improved system performance and efficiency overall.

Best Practices for Maintaining Flow Regulator Valve Efficiency

Maintaining the efficiency of flow regulator valves is critical for optimizing system performance in various industrial applications. Regular routine maintenance, including visual inspections and functionality tests, can significantly impact a valve's operational life. According to industry reports, improper maintenance can lead to a decrease in efficiency by as much as 25%, resulting in increased operational costs and potential system failures. Key practices such as ensuring that valves are free from debris, checking for leaks, and recalibrating settings based on specific operational conditions can help in sustaining performance levels.

Another vital aspect of maintenance involves monitoring the flow rates and ensuring they align with system specifications. A study conducted by the Fluid Control Association indicates that consistent monitoring can reveal inefficiencies and wear patterns, allowing for proactive adjustments before significant issues arise. Implementing a regular schedule for recalibrating valves and replacing worn or damaged components is essential for maintaining an optimal flow regulation system. By prioritizing these best practices, facilities can enhance the longevity and efficiency of their flow regulator valves, ultimately leading to lower energy consumption and greater overall productivity.

Related Posts

-

Future Trends in Best Flow Valve Market Analysis for 2025 Industry Outlook

-

How to Optimize Your System with Flow Regulator Valves for Maximum Efficiency

-

Understanding the Role of Flow Regulator Valves in Modern Fluid Control Systems

-

How to Choose the Right Pressure Regulator for Your Industrial Needs

-

Innovative Applications of Temperature Control Valves in Modern Industries

-

The Ultimate Guide to Understanding Water Pressure Regulators: How They Enhance Your Plumbing System