- Products

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

What is a Gate Valve and How Does it Work?

In the world of industrial piping systems, a "Gate Valve" plays a crucial role. As John Smith, a renowned valve expert, once said, "Gate valves are the unsung heroes of fluid control." They provide excellent flow characteristics. However, many people overlook their complexity and importance.

The Gate Valve operates by lifting a gate out of the path of the fluid. This design allows for minimal resistance to flow when fully open. Its simple mechanism can be both a strength and a weakness. While easy to operate, if neglected, it can lead to significant issues. Regular maintenance is vital, yet often ignored in many industries.

Understanding how a Gate Valve works can prevent costly mistakes. Misunderstandings about their operation could result in failures or inefficiencies. As industries push for innovation, it's crucial to examine these devices closely. The Gate Valve deserves more attention than it typically receives. Reflecting on their function can improve efficiency and reliability in systems worldwide.

What Is a Gate Valve? Definition and Key Features

A gate valve is a type of valve commonly used in pipelines. Its main purpose is to start or stop the flow of fluids. Unlike other valves, it operates by lifting a heavy gate out of the path of the fluid. This design allows for minimal flow resistance. The gate valve is quite effective in fully opening or closing applications.

Key features make gate valves unique. They have a simple construction, which contributes to their reliability. These valves are often used in large pipelines. When fully opened, they provide a straight path for fluid. This design reduces turbulence and pressure loss. However, they are not ideal for regulating flow. Partially open, some problems may occur, such as vibrations or noise.

While gate valves have significant benefits, they are not without drawbacks. They can be slow to operate. This might cause issues in emergencies. Regular maintenance is crucial to ensure longevity. If neglected, the gate can get stuck. This could lead to costly repairs or replacements. Understanding these aspects is important for optimal use.

The Anatomy of a Gate Valve: Components and Materials

A gate valve is a crucial component in many piping systems. Understanding its anatomy helps in proper application and maintenance. The main components of a gate valve include the body, gate, bonnet, and actuator. The body is typically made of cast iron or steel, providing durability. The gate, often made of brass or stainless steel, controls flow by rising or lowering within the valve seat.

The materials chosen for a gate valve affect its performance and lifespan. According to industry reports, stainless steel valves are preferred for high-pressure applications, showing over 2.5 times the lifespan compared to standard carbon steel valves. The valve bonnet houses the stem and actuator; materials here can impact sealing effectiveness. A well-sealed bonnet can prevent leaks, improving overall system efficiency.

However, many users overlook the importance of proper material selection. Using substandard materials can lead to premature failure. Studies show that nearly 30% of gate valve failures arise from corrosion and wear. Regular inspections can identify issues early, but maintenance remains a challenge. Users must be proactive to ensure longevity. Understanding the anatomy of a gate valve is essential for effective operation.

What is a Gate Valve and How Does it Work? - The Anatomy of a Gate Valve: Components and Materials

| Component | Material | Function | Common Sizes (inches) |

|---|---|---|---|

| Body | Cast Iron, Stainless Steel | Houses internal components and provides strength | 1 to 48 |

| Gate | Bronze, Stainless Steel | Controls flow by either opening or closing | 1 to 48 |

| Stem | Stainless Steel | Transmits motion from the actuator to the gate | 1 to 48 |

| Bonnet | Cast Iron, Stainless Steel | Covers the internal parts and connects to the body | 1 to 48 |

| Seals | Rubber, PTFE | Provides a leak-tight seal when the gate is closed | 1 to 48 |

How Gate Valves Operate: Mechanisms and Flow Control

Gate valves are essential components in many fluid systems. They feature a wedge-shaped disc that slides between two seats to control flow. When the valve is fully open, the path is clear, allowing maximum fluid flow. According to a recent report by the Valve Manufacturers Association, gate valves account for approximately 22% of total valve sales in the industry. This highlights their importance in water, gas, and steam applications.

The mechanism of gate valves relies on a simple yet effective design. When the actuator is turned, the disc moves vertically. This type of motion ensures minimal resistance when fully open. However, users often overlook that gate valves are not suitable for throttling. Operating them partially can lead to vibration and wear. Such issues may cause premature failure, reducing the valve's lifespan significantly. Research indicates that improper operation can lead to a 30% decrease in efficiency.

Flow control is critical in maintaining system integrity. When handling high-pressure applications, gate valves must be selected carefully. A mismatch can lead to leaks or bursts. Regular maintenance is key to their functionality. Monitoring wear and tear can help prevent costly breakdowns. It's essential for operators to know that choosing the right valve is not always straightforward. The performance may vary based on media and installation conditions.

Gate Valve Flow Control Performance

This chart demonstrates the operational metrics associated with gate valves, including pressure drop, flow rate, opening angle, and valve size, providing insights into the performance characteristics of gate valves in fluid control applications.

Applications of Gate Valves in Various Industries

Gate valves are widely used in various industries due to their efficient design. They are ideal for on/off applications. In the oil and gas sector, gate valves control the flow of crude oil and natural gas. Their ability to provide a tight seal minimizes leaks. However, if not maintained properly, they can rust and become difficult to operate.

In water treatment plants, gate valves help manage water flow effectively. They enable precise regulation, ensuring clean water delivery. The agricultural industry also benefits from these valves. Farmers use them for irrigation systems, directing water where it’s most needed. Yet, poor installation can lead to leaks and waste.

In power generation, gate valves play a critical role. They regulate steam and water flows, supporting efficient energy production. Despite their effectiveness, challenges can arise. For instance, sediment buildup can impair functionality. Regular inspection and maintenance are essential to avoid serious issues.

Comparative Analysis: Gate Valves vs Other Valve Types

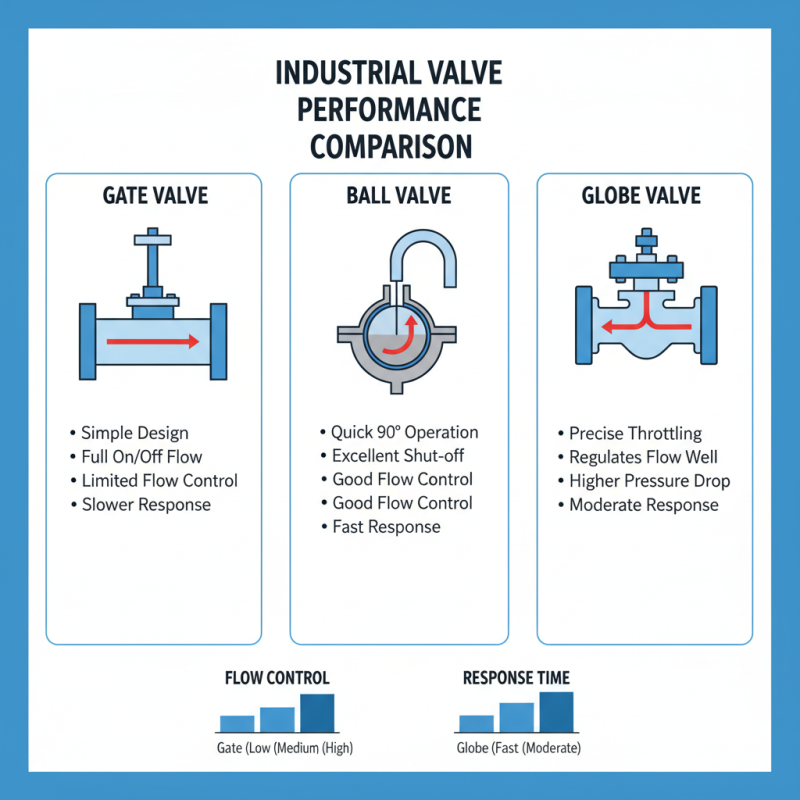

Gate valves are commonly used in various industrial applications due to their simple design and effectiveness. They operate by lifting a wedge out of the flow path, which can provide a full, unrestricted flow. However, their performance can vary significantly when compared to other valve types. For instance, ball valves and globe valves often outperform gate valves in terms of flow control and response times.

Recent industry reports indicate that gate valves can be less efficient in throttling applications. When partially open, they may cause water hammer or turbulence, leading to damage over time. In contrast, ball valves can handle throttling better with less pressure drop. A study by the Flow Control Association highlights that ball valves maintain a lower percentage of leakage compared to gate valves. In fact, leakage rates can soar up to 5% in gate valves under certain conditions.

While gate valves serve well in on/off applications, they might not be the best choice for dynamic flow conditions. The tendency for gate valves to become stuck due to sediment build-up is a notable concern. For processes requiring frequent adjustments, investing in a more suitable valve type could be wise. Ultimately, understanding the specific needs of the application is key for effective valve selection.

Related Posts

-

7 Essential Tips for Choosing the Right Gate Valve for Global Procurement Needs

-

Understanding Industry Standards for Best Slide Gate Valve Manufacturing Processes

-

How to Choose the Right Pressure Reducer for Your Needs

-

Understanding the Role of Gas Regulators in Safe Domestic and Industrial Applications

-

5 Essential Tips for Choosing Your Water Pressure Regulator Valve

-

Top 10 Pressure Reducing Valves: Essential Features and Benefits Explained