- Products

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

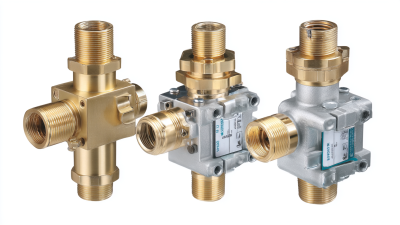

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

10 Reasons Pressure Regulator Valve is Essential for Industrial Applications

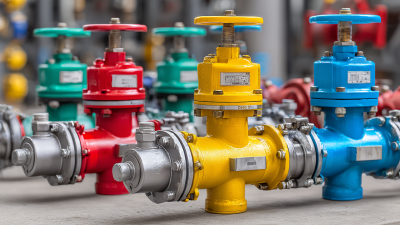

In the realm of industrial applications, the efficient and safe management of fluid systems is paramount. One critical component that plays a vital role in this process is the Pressure Regulator Valve. This essential device ensures that pressure levels are maintained consistently, preventing fluctuations that could lead to equipment failure or hazardous situations. By precisely controlling pressure, the Pressure Regulator Valve not only enhances operational efficiency but also protects vital machinery from damage caused by overpressure. In this blog, we will explore ten compelling reasons why the Pressure Regulator Valve is indispensable for industries ranging from manufacturing to energy production. Understanding its functions and benefits can significantly impact productivity, safety, and overall systems reliability, making it an essential fixture in any industrial setup.

Benefits of Pressure Regulator Valves in Industrial Settings

In industrial settings, the benefits of pressure regulator valves cannot be overstated. These vital components ensure optimal performance in various applications, including semiconductor and biotech industries. By maintaining consistent pressure levels, they protect equipment from damage and improve the reliability of operations, ultimately leading to enhanced productivity. Recent advancements in pressure regulators, such as those designed for ultra-high purity gas solutions, demonstrate the evolving capabilities of these devices to meet specific demands.

Moreover, innovative solutions like redundant working monitor regulator configurations have proven effective in addressing pressure control issues, as seen in high-demand environments like fuel gas applications. These improvements not only stabilize pressure but also enhance safety, preventing potential hazards associated with fluctuating pressure levels. As industries continue to advance, the integration of advanced pressure regulators and control valves will be essential for maintaining efficiency and achieving operational excellence.

Key Features to Look for in a Pressure Regulator Valve

When selecting a pressure regulator valve for industrial applications, several key features must be prioritized to ensure optimal performance and reliability. One of the most critical aspects is the valve's accuracy in maintaining pressure within specified limits. According to a recent report by the International Society of Automation, systems that utilize precision pressure regulators can improve process efficiency by up to 30%. This accuracy can prevent equipment damage and enhance safety protocols, making it an indispensable component in sectors like oil and gas, pharmaceuticals, and food processing.

Another essential feature to consider is the material construction of the pressure regulator valve. A study published by the Materials Research Society indicates that valves made of corrosion-resistant materials, such as stainless steel or plastic composites, can significantly prolong service life, even in aggressive environments. For instance, valves designed for high-temperature applications have been shown to withstand pressures exceeding 150 psi, proving their suitability for demanding industrial settings. Thus, selecting the right pressure regulator valve, equipped with these key features, is crucial for efficient operations and long-term reliability in various industrial sectors.

How Pressure Regulator Valves Improve Safety in Operations

Pressure regulator valves play a crucial role in enhancing safety across various industrial operations. By maintaining a consistent outlet pressure, these valves prevent dangerous pressure spikes that can lead to equipment failure or catastrophic accidents. For instance, in process industries where gases or liquids are transported, fluctuations in pressure can result in leaks or ruptures. By regulating the pressure within a defined range, these valves help protect both personnel and machinery, minimizing the risks associated with high-pressure operations.

Moreover, pressure regulator valves contribute to the overall efficiency of industrial systems. By controlling pressure levels, they ensure that equipment operates within safe and optimal parameters, reducing the likelihood of wear and tear due to extreme pressure variations. This not only prolongs the lifespan of the equipment but also lowers maintenance costs and minimizes downtime. As operators can rely on stable pressure readings, they can focus on productivity without the constant worry of pressure-related incidents, fostering a safer and more efficient work environment.

Steps to Properly Install and Maintain Pressure Regulator Valves

Proper installation and maintenance of pressure regulator valves are crucial for their optimal performance in industrial applications.

The first step in installation is selecting the right valve for your specific system requirements, taking into account factors like pressure rating, flow capacity, and media compatibility.

Once the appropriate valve is chosen, ensure that the installation area is accessible, clean, and free from debris.

Position the valve so that it is in line with the piping, and use the manufacturer's specifications for torque settings to avoid damage during installation.

Maintenance is equally important in ensuring the longevity and efficiency of pressure regulator valves.

Regularly inspect the valve for signs of wear or damage, particularly in the diaphragm and spring components, as these are often subject to fatigue.

It is advisable to implement a routine maintenance schedule that includes cleaning the valve and checking for leaks.

Additionally, testing the pressure settings periodically can help ensure the valve is operating within its designed parameters, preventing potential failures that could disrupt industrial processes.

By following these steps, industries can maximize their investment in pressure regulator valves and enhance overall system reliability.

Common Applications of Pressure Regulator Valves in Various Industries

Pressure regulator valves play a crucial role in various industrial applications, ensuring that systems operate efficiently and safely. These valves help maintain consistent pressure levels, which is essential in sectors such as manufacturing, oil and gas, and water treatment. For instance, in the oil and gas industry, pressure regulator valves are vital for controlling the pressure of gas and ensuring that equipment operates within safe limits. Similarly, in the water treatment industry, these valves help manage the pressure of water streams to optimize treatment processes.

The importance of pressure regulator valves is underscored by industry forecasts. The global bearing market is expected to reach a value of $46.82 billion in 2024 and is projected to grow to $97.1 billion by 2032. This rapid growth reflects the increasing demand for various industrial components, including pressure regulators. Furthermore, the OpenStack services market in the U.S. is set to experience significant expansion, with projections indicating an increase from $5.71 billion in 2023 to $44.84 billion by 2032. As industries evolve and technology advances, the role of pressure regulator valves in maintaining operational efficiency cannot be overstated.

Common Applications of Pressure Regulator Valves in Various Industries

The chart above illustrates the importance level of pressure regulator valves across various industrial applications. The values range from 1 to 10, where higher values reflect a greater necessity for pressure regulation in that industry.

Related Posts

-

Mastering High Pressure Regulation: A Step-by-Step Guide to Choosing the Best Regulator

-

Top 5 Innovative Applications of the Best High Pressure Regulators in Various Industries

-

Top Strategies for Maximizing Efficiency with High Pressure Regulators

-

Exploring Unique Examples of Pressure Valve Applications in Industrial Processes

-

5 Essential Tips for Choosing Your Water Pressure Regulator Valve

-

10 Essential Reasons to Choose the Best Gas Regulator Valve for Your Needs