- Products

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

Understanding Industry Standards for Best Slide Gate Valve Manufacturing Processes

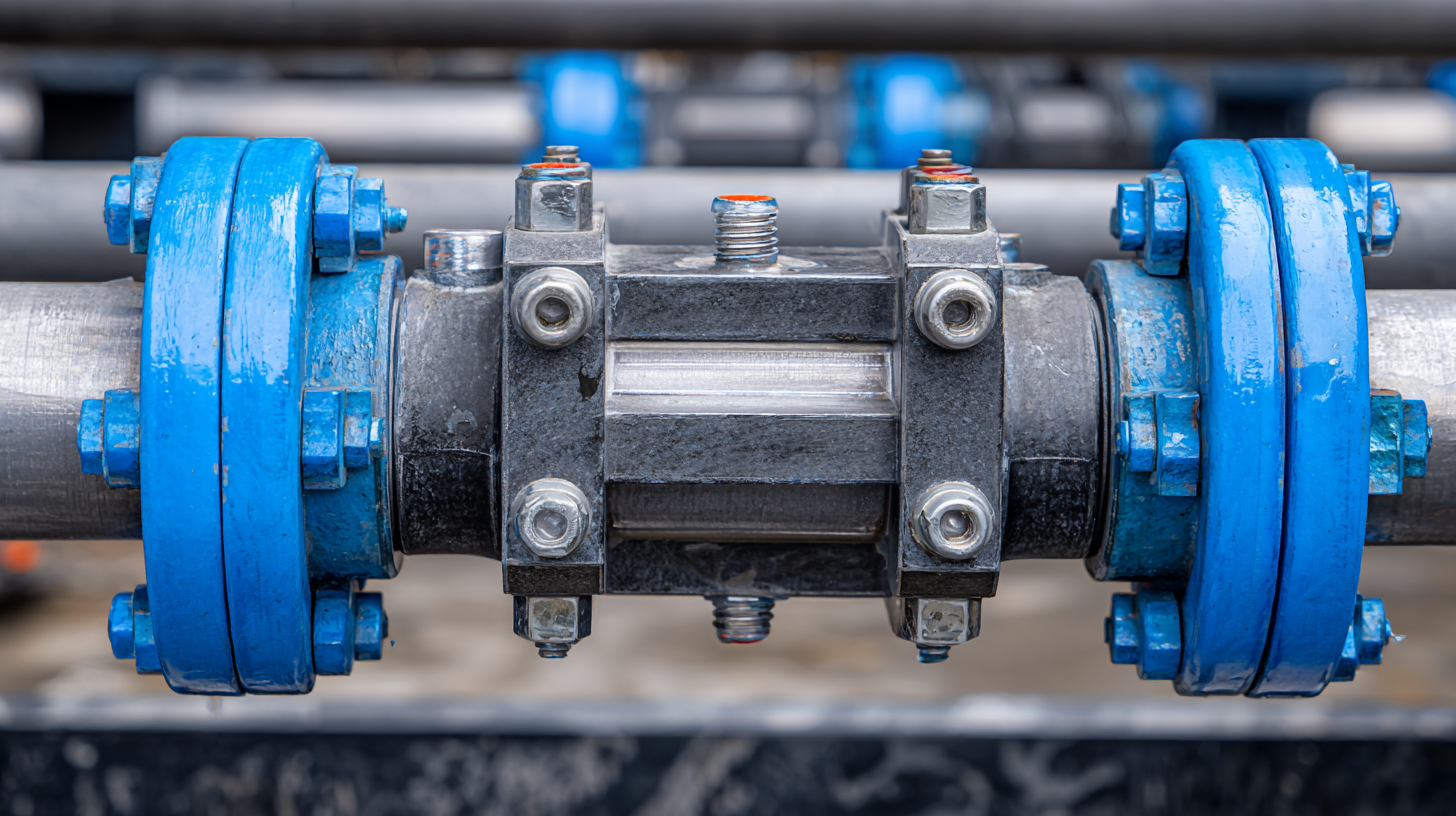

In the realm of valve manufacturing, understanding industry standards for the best slide gate valve processes is imperative for ensuring quality and reliability. According to a report by Research and Markets, the global valve market is projected to reach $100 billion by 2025, with slide gate valves being a critical component across multiple sectors, including water treatment, oil and gas, and chemical processing. These valves are renowned for their ability to provide efficient isolation and flow control, which directly influences operational safety and efficiency. As manufacturers strive for excellence, adhering to recognized industry standards not only enhances product performance but also fosters competitive advantage. This blog will explore the essential manufacturing processes, materials, and quality control measures that distinguish top-tier slide gate valves within this expansive and evolving market.

Key Manufacturing Techniques for High-Quality Slide Gate Valves

In the realm of slide gate valve manufacturing, employing key techniques that adhere to industry standards is paramount for producing high-quality products. Techniques such as precision machining, surface treatment, and stringent quality control processes are integral to ensuring that these valves operate effectively in various applications, including oil and gas, water, and wastewater management. A vital aspect of this manufacturing process is the careful selection of materials, which directly influences the durability and performance of the final product.

Recent developments in the valve industry highlight the importance of innovation and adaptability. For instance, a notable breakthrough was achieved with a major contract, underscoring the growing demand for advanced valve solutions. Furthermore, the instrumentation valve market is anticipated to expand significantly, driven by the increasing need for reliable and efficient operations across various sectors. By integrating modern technologies such as artificial neural networks for predictive analytics in manufacturing, companies can enhance productivity and reduce failures in their processes, ultimately leading to better performance of slide gate valves in the demanding environments they serve.

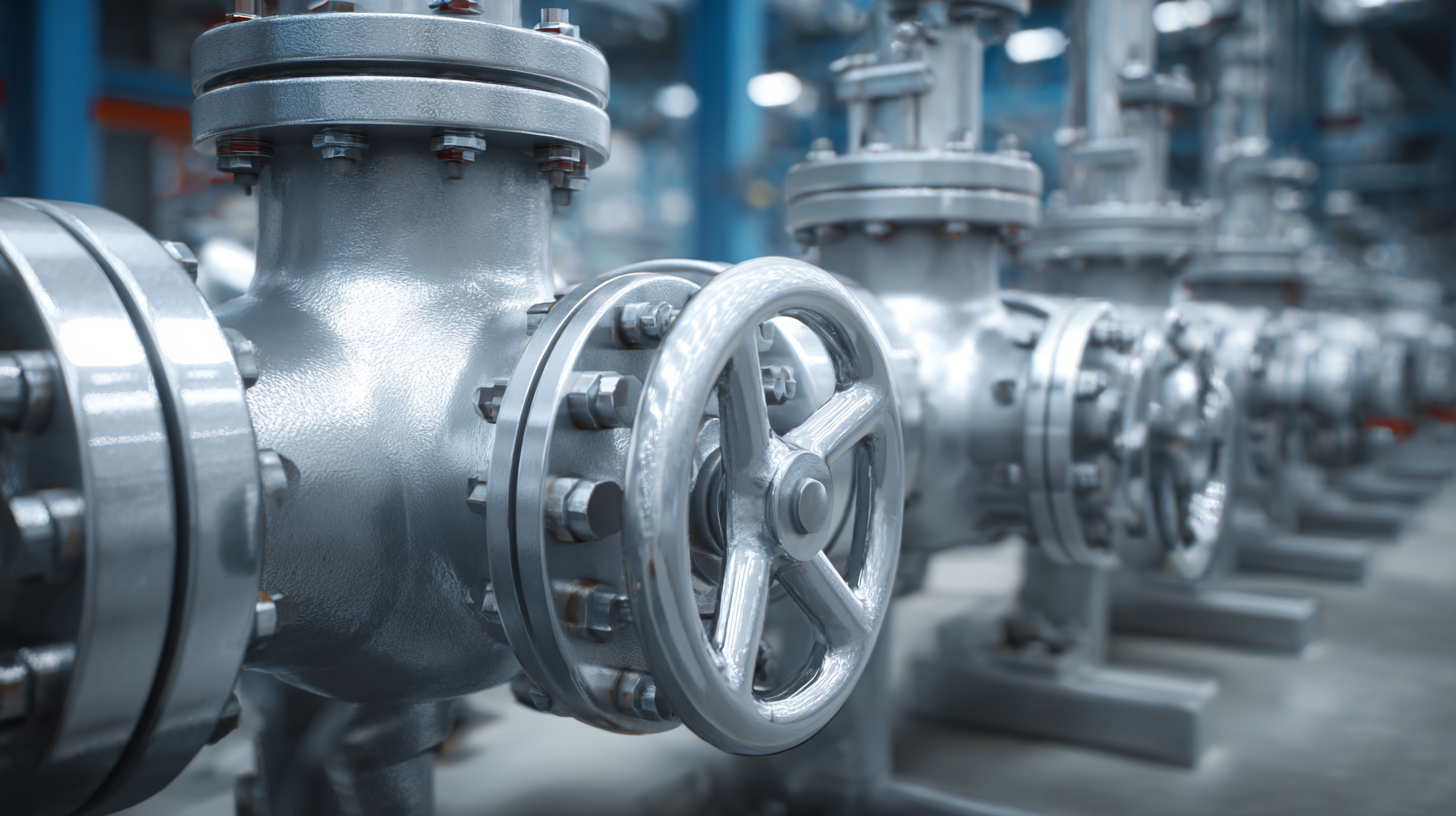

Critical Industry Standards Guiding Slide Gate Valve Production

The production of slide gate valves is governed by a variety of industry standards that ensure the reliability and safety of these critical components. Compliance with standards such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) is essential for manufacturers. These guidelines dictate materials, design specifications, and testing procedures that help maintain consistency and quality across the production process. For instance, ASTM standards provide detailed criteria for the mechanical properties of materials used in valve manufacturing, thereby ensuring that the final product can withstand the rigorous demands of various industrial applications.

In addition to material standards, manufacturers must also adhere to specific operational and performance criteria set forth by organizations such as the American National Standards Institute (ANSI). These criteria focus on the functionality of slide gate valves, including aspects such as pressure ratings, flow characteristics, and sealing capabilities. By aligning production processes with these critical industry standards, manufacturers not only enhance the performance of their products but also instill confidence in their customers regarding the reliability and longevity of the valves. Embracing these standards fosters innovation and quality, ultimately contributing to safer and more efficient industrial operations.

Innovative Materials and Their Impact on Valve Performance

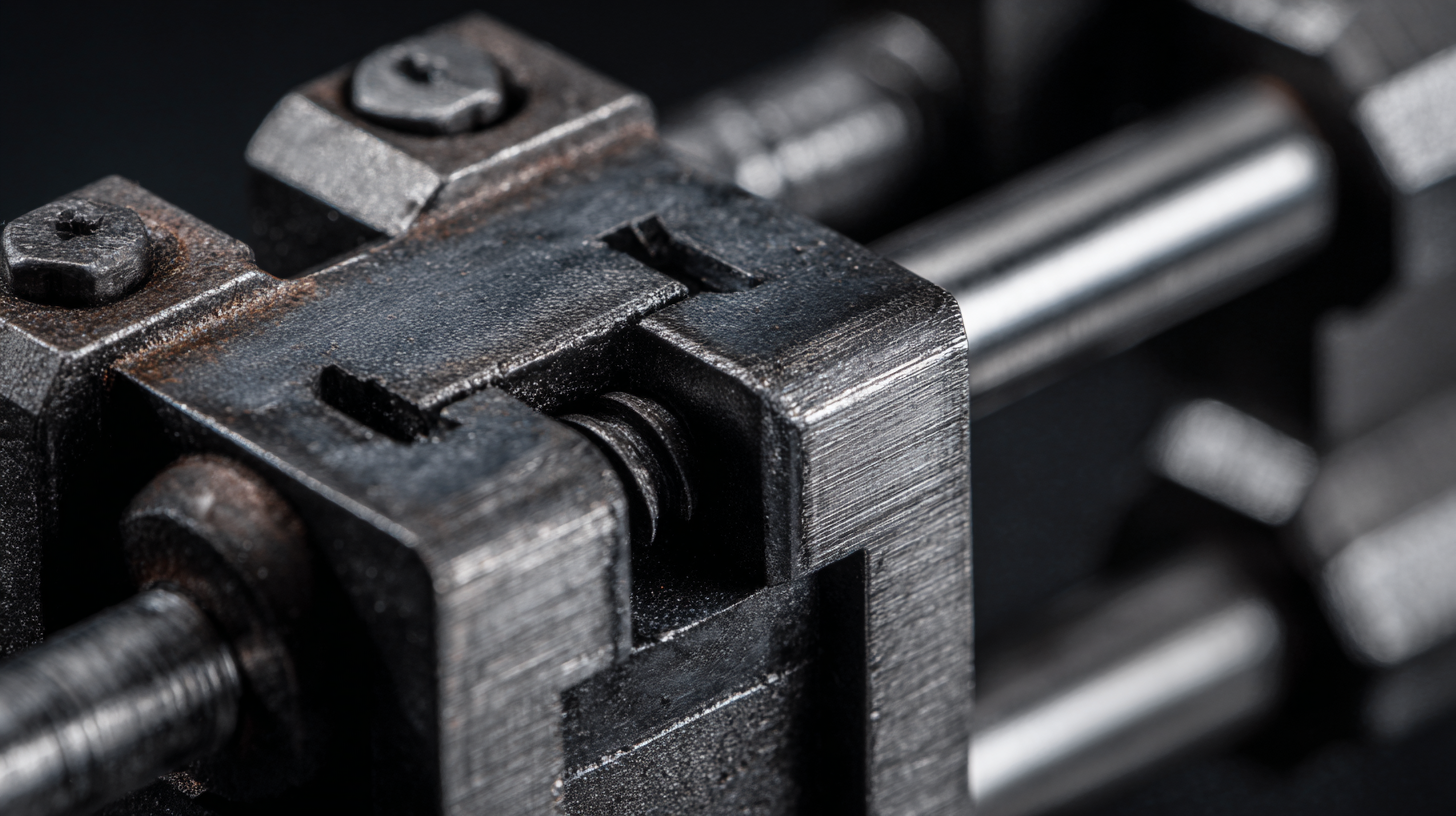

Innovative materials play a crucial role in enhancing the performance of slide gate valves in various industrial applications. The right material choice not only ensures durability and resistance to corrosion but also directly impacts the efficiency of the valve. Lightweight and high-strength materials, such as advanced polymers and composite materials, have emerged as game-changers, enabling manufacturers to design valves that can withstand extreme conditions while maintaining optimal performance.

Tip: When selecting materials for slide gate valve manufacturing, consider factors such as temperature resistance, pressure ratings, and chemical compatibility to ensure a long-lasting and reliable product.

Utilizing innovative alloys and coatings can also significantly improve the slide gate valve's lifespan and functionality. For instance, ceramic coatings can reduce friction and create a smoother operating surface, which minimizes wear and tear over time. Additionally, the adoption of smart materials that respond to environmental changes opens new avenues for improving valve automation and control.

Tip: Regularly assess the performance of materials in service conditions, as this will help identify potential enhancements that can further optimize valve performance and extend its operational life.

Quality Control Measures Essential in Slide Gate Valve Manufacturing

In the manufacturing process of slide gate valves, quality control measures are paramount to ensure reliability and performance. These valves are critical components in various industrial applications, and any defects can lead to operational failures. Implementing stringent quality control protocols at every stage of production helps to minimize risks and ensures that the final product meets industry standards.

One essential tip for enhancing quality control is to utilize advanced inspection technologies. Employing non-destructive testing methods, such as ultrasonic or radiographic testing, can help identify internal flaws without damaging the component. Additionally, regular calibration of measurement tools ensures precision and consistency in the manufacturing process.

Another crucial aspect is to foster a culture of quality among workers. Training employees on the importance of quality control and the specific standards that must be met can significantly improve outcomes. Encouraging a mindset of continuous improvement not only boosts employee engagement but also leads to better manufacturing practices and a reduction in defects over time.

Quality Control Measures in Slide Gate Valve Manufacturing

Adapting to Technological Advances in Valve Production Processes

The landscape of valve manufacturing is undergoing a significant transformation, driven by rapid technological advancements. As industries increasingly prioritize efficiency and reliability, the need for innovative production processes has become paramount. Embracing automation and smart manufacturing techniques, manufacturers can enhance the precision and quality of slide gate valves, thereby aligning with industry standards that demand higher performance and durability.

In the context of the HPLC check valve and ball valve seat market, projected to grow from $21.27 million in 2024 to $34.93 million by 2032, this evolution is particularly relevant. The anticipated growth rate of 6.39% indicates a strong demand for valves that not only meet but exceed traditional specifications. To capture this expanding market, manufacturers must adapt their processes to integrate cutting-edge technologies, such as advanced materials and real-time analytics, which promote greater operational efficiency and adaptability to market needs. By focusing on these adaptations, valve producers can secure their positions at the forefront of an increasingly competitive industry.