- Products

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

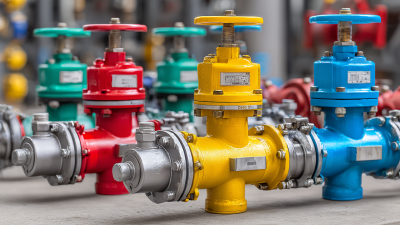

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

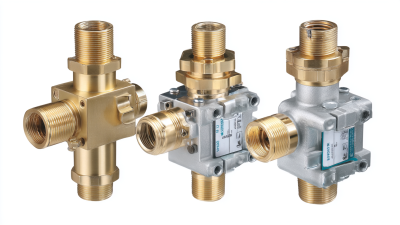

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

Top Strategies for Maximizing Efficiency with High Pressure Regulators

In the realm of gas and fluid management, the significance of a High Pressure Regulator cannot be overstated. According to recent industry reports, nearly 30% of operational inefficiencies in process industries can be traced back to inadequate pressure control systems. High pressure regulators play a crucial role in maintaining optimal pressure levels, ensuring safety and efficiency in diverse applications, from chemical processing to oil and gas operations. As businesses strive for cost reduction and enhanced productivity, implementing advanced high pressure regulation strategies becomes paramount. With the growing emphasis on sustainable practices, optimizing the utilization of these regulators not only mitigates wastage but also aligns with environmental compliance standards. This blog will explore top strategies that organizations can adopt to maximize the efficiency of their high pressure regulators while highlighting the latest innovations in the field.

Understanding High Pressure Regulators: Key Components and Functionality in Efficiency Optimization

High pressure regulators are essential components in optimizing efficiency across various industrial applications. Understanding their key components, such as the pressure sensing system, control valve mechanism, and diaphragm, is critical in maximizing performance. These mechanisms work together to maintain a consistent output pressure, which is crucial for processes reliant on precise pressure measurements. By implementing smart technologies, including machine learning and real-time monitoring systems, industries can enhance the reliability and response of high pressure regulators, ensuring their operations remain efficient and effective.

High pressure regulators are essential components in optimizing efficiency across various industrial applications. Understanding their key components, such as the pressure sensing system, control valve mechanism, and diaphragm, is critical in maximizing performance. These mechanisms work together to maintain a consistent output pressure, which is crucial for processes reliant on precise pressure measurements. By implementing smart technologies, including machine learning and real-time monitoring systems, industries can enhance the reliability and response of high pressure regulators, ensuring their operations remain efficient and effective.

Recent advancements in automation and energy management further underscore the importance of integrating high pressure regulators within intelligent systems. Innovations such as predictive maintenance and condition monitoring enable industries to proactively address potential issues before they disrupt operations. Furthermore, by leveraging data analytics, companies can optimize their processes, contributing to sustainable practices and reducing operational costs. In a landscape increasingly influenced by technology, understanding and optimizing the functionality of high pressure regulators becomes indispensable for organizations striving to maximize efficiency and sustainability.

Selecting the Right High Pressure Regulator: Factors Impacting Performance and Efficiency

When selecting the right high pressure regulator, several factors can significantly impact performance and efficiency. One of the first considerations is flow rate requirements. It's crucial to choose a regulator that can handle the maximum flow rate of your application without causing pressure drops that could affect system performance. This means checking manufacturer specifications against your operational needs to ensure optimal performance.

Another vital factor is the material compatibility of the regulator. Different applications involve various gases and environments that may lead to corrosion or degradation of materials. Choose materials that are resistant to the specific chemicals they will come into contact with. This ensures the regulator maintains its integrity over time, contributing to more reliable operation and reduced maintenance costs.

Tips:

- Always verify the inlet and outlet pressure ranges to ensure they match your system requirements.

- Regularly inspect and maintain your high pressure regulator to catch potential issues early, ensuring consistent efficiency.

- Consider using a regulator with adjustable settings, allowing for greater flexibility in different operational scenarios.

Top Strategies for Maximizing Efficiency with High Pressure Regulators

| Factor | Impact on Performance | Efficiency Gain (%) | Recommended Type |

|---|---|---|---|

| Inlet Pressure Range | Directly affects flow consistency | 15% | Single-stage regulators |

| Temperature Regulation | Influences material integrity | 20% | Linkage temperature compensator |

| Output Pressure Control | Essential for downstream processes | 25% | Adjustable regulators |

| Material Selection | Resilience against contaminants | 10% | Corrosion-resistant materials |

| Maintenance Schedule | Ensures operational reliability | 30% | Regularly serviced units |

Impact of Pressure Gradients: Data-Driven Insights on Pressure Variability and System Performance

Understanding the impact of pressure gradients is essential for optimizing the performance of high pressure regulators in various systems. Pressure variability can significantly affect not only the efficiency of flow control but also system stability. By analyzing data on pressure fluctuations, engineers can identify critical points where pressure losses occur, allowing them to implement targeted improvements. For instance, maintaining a consistent pressure gradient within a system minimizes the risk of cavitation and the wear and tear of equipment, leading to prolonged service life and reduced maintenance costs.

Moreover, leveraging data-driven insights enables the development of more sophisticated regulatory strategies. Real-time monitoring of pressure values allows for dynamic adjustments in response to changing conditions, ensuring that systems operate within optimal parameters. This proactive approach can enhance both safety and productivity. By employing advanced modulation techniques and predictive analytics, organizations can not only respond to issues as they arise but also anticipate potential variances, enhancing overall system reliability and maximizing efficiency in high pressure regulation processes.

Maintenance Best Practices: Ensuring Longevity and Efficiency in High Pressure Regulation Systems

Maintaining high pressure regulation systems is crucial for ensuring their longevity and optimal performance. Regular inspections can help identify wear and tear, allowing for timely repairs before they escalate. It is advisable to check the seals and connections routinely, as any leaks can compromise efficiency. Additionally, ensuring that the regulator is clean from debris from the environment will help maintain its performance, preventing unnecessary strain on the system.

Tips: Always schedule regular maintenance in line with the manufacturer’s recommendations. This includes not only physical inspections but also testing the system under operational conditions to ensure it’s functioning correctly. Using high-quality, compatible components during repairs can further enhance system reliability.

Proper lubrication of moving parts is essential for reducing friction and wear. Ensure that you are using the correct lubricants suited for the specific materials of your regulator. A well-lubricated system not only operates more smoothly but also reduces the risk of component failure. Lastly, keep documentation of maintenance activities; this will help track performance trends and predict future maintenance needs effectively.

Case Studies: Real-World Applications Demonstrating Efficiency Gains with Proper Regulation Techniques

In the realm of industrial applications, the strategic use of high-pressure regulators can lead to significant efficiency gains, as illustrated by various case studies from different sectors. For instance, a report by the Gas Technology Institute highlights that manufacturers leveraging advanced regulator systems reported up to a 30% reduction in energy consumption. This reduction is often achieved by optimizing the flow rates and pressure levels, allowing for more precise control over the processes and minimizing waste.

One compelling case study comes from the food processing industry, where a leading company implemented high-pressure regulators within its gas distribution system. By doing so, they achieved a 25% increase in production efficiency, primarily due to the elimination of pressure spikes that previously caused production delays. Similarly, in the chemical sector, a study by the American Institute of Chemical Engineers revealed that consistent pressure regulation led to a 20% improvement in reaction rates due to enhanced system stability. These real-world applications demonstrate that with the right regulation techniques, industries can not only optimize their operations but also significantly enhance overall efficiency.

Related Posts

-

Mastering High Pressure Regulation: A Step-by-Step Guide to Choosing the Best Regulator

-

10 Essential Reasons to Choose the Best Gas Regulator Valve for Your Needs

-

5 Essential Tips for Choosing Your Water Pressure Regulator Valve

-

Future Trends in Best Flow Valve Market Analysis for 2025 Industry Outlook

-

Navigating Import and Export Certifications for the Best Gas Regulators in the Market

-

Top 5 Innovative Applications of the Best High Pressure Regulators in Various Industries