- Products

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

How to Optimize Your System with Flow Regulator Valves for Maximum Efficiency

In today's competitive industrial landscape, optimizing system efficiency is paramount for reducing operational costs and maximizing productivity. According to a recent report from the International Energy Agency, systems that incorporate precision controls can achieve energy savings of up to 30%. One crucial component in this optimization process is the Flow Regulator Valve, which ensures consistent flow rates and minimizes fluctuations that can lead to inefficiencies. By effectively managing fluid dynamics within various applications, these valves play a vital role in enhancing system performance and reliability. As industries increasingly turn to automation and advanced technologies, understanding how to leverage Flow Regulator Valves becomes essential for engineers and facility managers striving for sustainable operational excellence.

Understanding Flow Regulator Valves and Their Importance in Systems

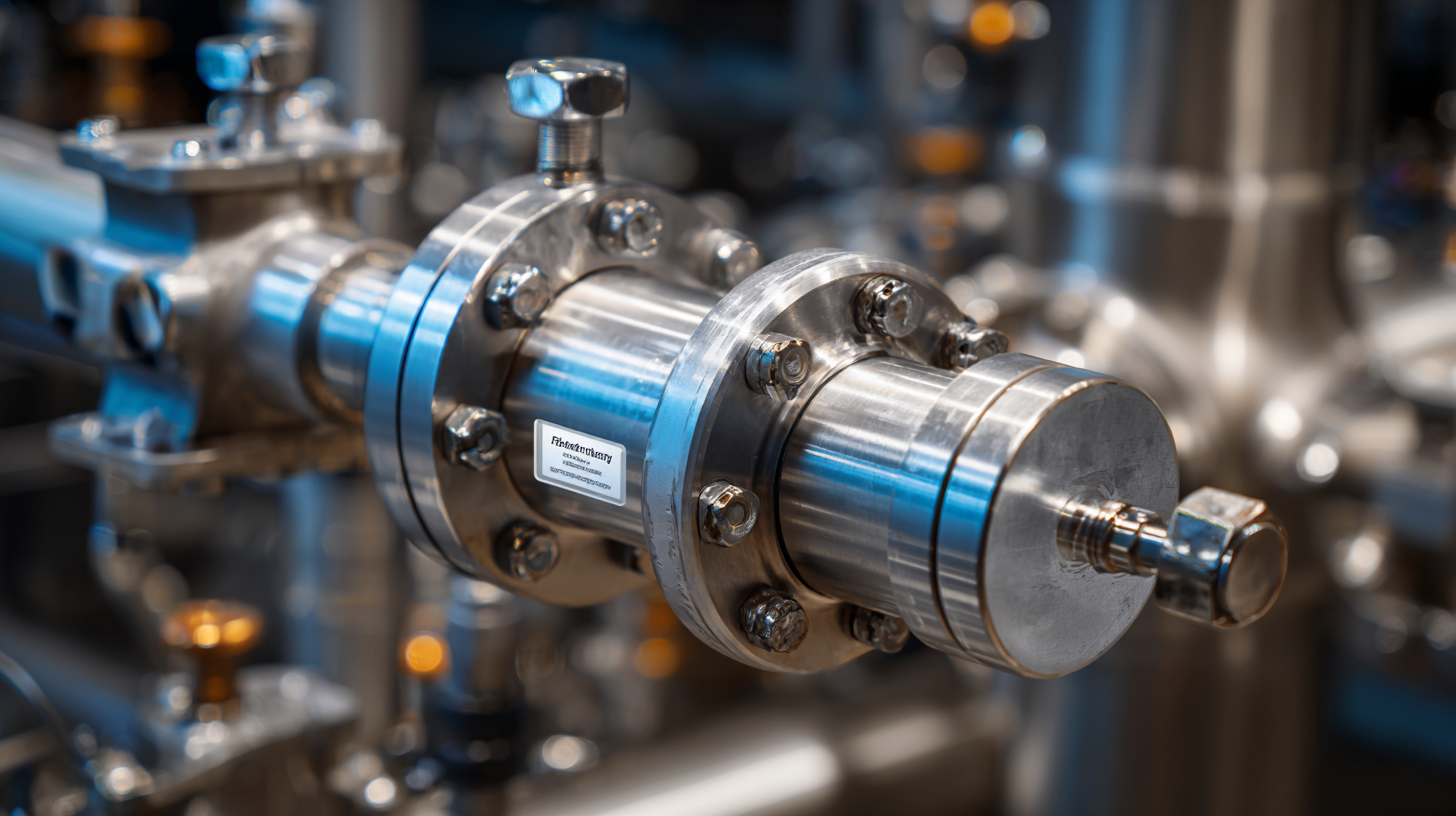

Flow regulator valves play a critical role in optimizing system performance across various applications, from industrial processes to HVAC systems. These valves are designed to maintain a consistent flow rate, regardless of changes in pressure or downstream demand. By doing so, they ensure that systems operate efficiently, reducing energy consumption and preventing potential damage from fluctuations in flow. Understanding the mechanics behind these valves allows engineers and operators to implement them effectively, maximizing system efficiency.

Flow regulator valves play a critical role in optimizing system performance across various applications, from industrial processes to HVAC systems. These valves are designed to maintain a consistent flow rate, regardless of changes in pressure or downstream demand. By doing so, they ensure that systems operate efficiently, reducing energy consumption and preventing potential damage from fluctuations in flow. Understanding the mechanics behind these valves allows engineers and operators to implement them effectively, maximizing system efficiency.

Furthermore, the importance of flow regulator valves extends beyond mere flow control. They are instrumental in protecting sensitive equipment, ensuring that processes remain stable and predictable. For example, in a cooling system, maintaining a steady flow of coolant is essential to avoid overheating and ensure performance. Additionally, effective flow regulation can lead to significant cost savings by minimizing waste and promoting optimal resource usage. As industries seek to improve sustainability and reduce operational costs, the implementation of flow regulator valves becomes increasingly vital in achieving these goals.

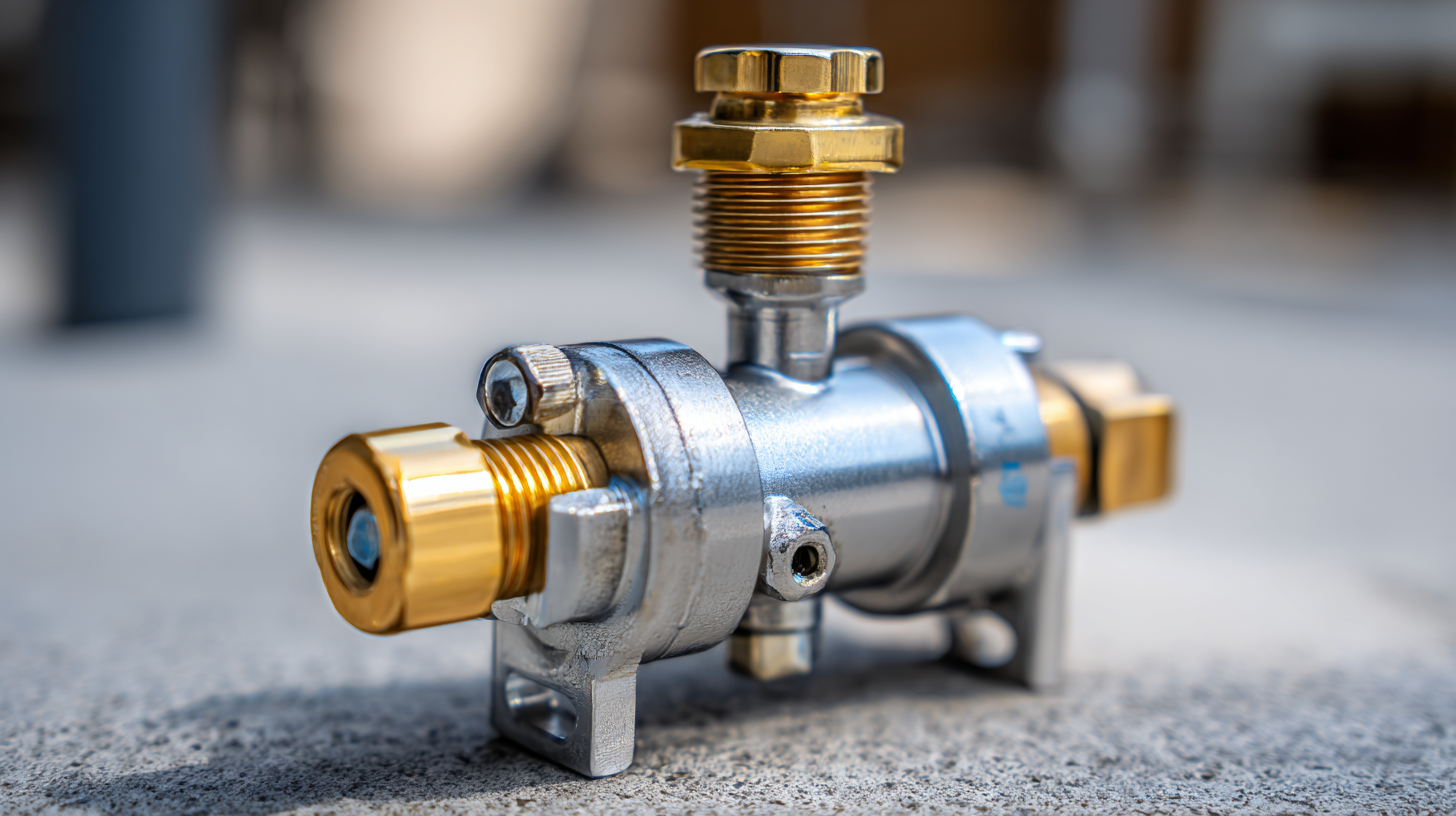

Types of Flow Regulator Valves and Their Specific Applications

Flow regulator valves play a crucial role in optimizing system efficiency across various industries by managing fluid flow to desired levels. Typically categorized into two main types—pressure-regulated and flow-regulated valves—each has unique applications tailored to specific needs. For instance, pressure-regulated valves are often employed in hydraulic systems to maintain a steady pressure, ensuring equipment longevity and optimal performance. According to a report by the International Society for Fluid Dynamics, systems using pressure-regulated valves can achieve up to 25% higher operational efficiency compared to those without them.

On the other hand, flow-regulated valves, such as needle and diaphragm valves, are essential in irrigation and manufacturing, where precise flow control is vital. The American Water Works Association notes that using flow regulator valves in irrigation systems can reduce water consumption by as much as 30%, demonstrating their effectiveness in promoting sustainability. Additionally, these valves help prevent system overloading by ensuring consistent flow rates, thus safeguarding sensitive equipment. As industries continue to seek efficiency, the integration of these specialized valves is expected to become increasingly prevalent, further optimizing operational performance.

Key Factors to Consider for Optimizing Efficiency with Flow Regulators

When optimizing systems with flow regulator valves, several key factors significantly influence efficiency. First and foremost, understanding the flow characteristics of the application is crucial. According to a report by the International Society of Automation, proper matching of flow rates with the regulator's specifications can lead to energy savings of up to 20%. This demonstrates the importance of selecting appropriate valve sizes and types to avoid energy waste and ensure optimal performance.

Another essential consideration is the material and design of the flow regulator. The right materials can impact not only the longevity of the valves but also their efficiency in handling different media. For instance, a study from the American Society of Mechanical Engineers highlights that using corrosion-resistant materials, optimized for the specific fluid characteristics, can extend valve life and maintain performance integrity, resulting in a 15% reduction in maintenance costs over a valve's lifecycle. Consequently, investing in quality flow regulators tailored to specific applications can lead to substantial long-term savings and system reliability.

Best Practices for Installing and Maintaining Flow Regulator Valves

When it comes to optimizing system performance, the installation and maintenance of flow regulator valves play a pivotal role. To achieve maximum efficiency, it is essential to adhere to best practices throughout the installation process. Begin by selecting the right type of flow regulator valve for your specific application, as each type has unique characteristics suited for different fluid systems. Proper sizing is crucial; utilizing a valve that matches the flow requirements prevents pressure drops and enhances overall system functionality. Ensure that the installation area is clean and free of debris to avoid any potential blockage that could impede flow.

Once installed, regular maintenance is key to sustaining optimal performance. Routine inspections should be conducted to check for signs of wear and tear or any leaks that may compromise efficiency. It is advisable to clean the valves periodically to prevent buildup and obstructions, which can alter flow rates. Keeping detailed records of maintenance activities will help anticipate future issues and streamline troubleshooting. Additionally, familiarize yourself with manufacturer guidelines, as they provide valuable insights on the recommended maintenance intervals and procedures specific to the valve type in use, ensuring that your system operates seamlessly over time.

Flow Regulator Valve Efficiency Optimization

This chart illustrates the improvement in system efficiency before and after the optimization of flow regulator valves. Initial efficiency was measured at 60%, which increased to 85% post-optimization, showcasing the importance of proper installation and maintenance practices.

Common Challenges in Flow Regulation and How to Overcome Them

Flow regulation is crucial in various systems, yet it often presents several challenges that can hinder efficiency. One common challenge is fluctuating pressure conditions, which can lead to inconsistent flow rates. This inconsistency can cause strain on the system, resulting in energy loss and increased operational costs. To overcome this, implementing advanced flow regulator valves that can automatically adjust to pressure variations is essential. These valves ensure steady flow, optimizing system performance and reducing wear and tear on your machinery.

Another significant challenge is the accumulation of debris and buildup in pipes, which can restrict flow and create pressure drops. Regular maintenance often becomes necessary; however, this can be an unwelcome disruption to operations. To mitigate this issue, incorporating filters or using flow regulator valves designed to handle particles effectively can significantly enhance long-term efficiency. Additionally, educating staff on the importance of system checks and employing smart monitoring technology can further prevent flow regulation issues before they escalate. By addressing these challenges head-on, businesses can significantly improve their system's efficiency and reliability.

How to Optimize Your System with Flow Regulator Valves for Maximum Efficiency

| Dimension | Measurement | Best Practices | Common Challenges | Solutions |

|---|---|---|---|---|

| Flow Rate | gallons per minute (GPM) | Regular monitoring | Inconsistent flow | Install flow sensors |

| Pressure Levels | pounds per square inch (PSI) | Optimize for system needs | Pressure drops | Adjust regulator settings |

| Temperature Control | degrees Fahrenheit (°F) | Calibrate regularly | Overheating systems | Install temperature sensors |

| System Efficiency | percentage (%) | Regular maintenance | Energy losses | Perform energy audits |

Related Posts

-

Future Trends in Best Flow Valve Market Analysis for 2025 Industry Outlook

-

Mastering High Pressure Regulation: A Step-by-Step Guide to Choosing the Best Regulator

-

Understanding Industry Standards for Best Slide Gate Valve Manufacturing Processes

-

10 Reasons Pressure Regulator Valve is Essential for Industrial Applications

-

Top Strategies for Maximizing Efficiency with High Pressure Regulators

-

How to Choose the Right Water Regulator Valve for Your Industrial Needs