- Products

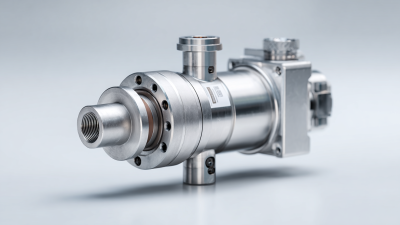

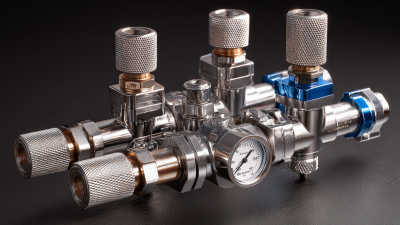

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

Exploring Unique Examples of Pressure Valve Applications in Industrial Processes

In the realm of industrial processes, pressure valves play a pivotal role in ensuring safety and efficiency across various applications. These critical components are designed to regulate and control pressure levels, mitigating the risks associated with over-pressurization. As industries evolve, the demand for innovative and unique pressure valve applications has surged, leading to advancements that enhance performance and reliability. This blog delves into the fascinating world of pressure valve applications, providing a checklist of unique examples that highlight their diverse functionalities—from oil and gas to pharmaceuticals and food processing. By exploring these distinct cases, we aim to illuminate the significance of pressure valves in optimizing industrial operations and sustaining safety standards, ultimately showcasing their indispensable value across multiple sectors.

Importance of Pressure Valves in Maintaining Safety Standards in Industrial Operations

Pressure valves play a crucial role in ensuring safety standards across various industrial operations. According to the U.S. Occupational Safety and Health Administration (OSHA), improper management of pressure systems can lead to catastrophic incidents, including explosions and equipment failures. A report by the National Institute for Occupational Safety and Health (NIOSH) indicates that nearly 25% of industrial accidents are linked to malfunctioning pressure equipment. This statistic underscores the critical function of pressure valves in maintaining safe operational environments, as they regulate and control the pressure within systems, preventing excessive pressure buildup that could lead to accidents.

Furthermore, a survey from the American Society of Mechanical Engineers (ASME) highlights that industries utilizing pressure valves, such as oil and gas, chemical processing, and power generation, have experienced a significant decrease in workplace incidents—up to 40%—after implementing advanced pressure management systems. These systems not only enhance safety but also improve operational efficiency by optimizing pressure control mechanisms. Investment in high-quality pressure valves and proper maintenance protocols is essential for ensuring compliance with safety regulations and protecting both personnel and assets.

Innovative Applications of Pressure Valves in Oil and Gas Extraction Processes

Pressure valves play a crucial role in the oil and gas extraction processes, contributing significantly to efficiency and safety in industrial operations. Recent advancements in technology have led to innovative applications of these valves, particularly in enhancing the efficacy of extraction methods. For example, the integration of pressurized liquid extraction coupled with real-time monitoring systems provides an efficient means of extracting valuable compounds, such as polyphenols from green propolis. This method not only optimizes the extraction process but also ensures adherence to sustainability practices by reducing waste and energy consumption.

Moreover, the application of gas lift techniques in oil recovery illustrates how pressure valves can maximize production, as evidenced by the case study conducted in the Asmari formation. By optimizing these gas lift processes, operators can enhance recovery rates significantly, highlighting the critical role of pressure valves in facilitating innovative solutions within the industry. The continual exploration and implementation of these technologies indicate a promising future for pressure valves in not just oil and gas extraction, but also in various other industrial processes, reinforcing their importance in achieving operational excellence.

Exploring Unique Examples of Pressure Valve Applications in Industrial Processes

| Application Area | Pressure Valve Type | Functionality | Impact on Process | Notes |

|---|---|---|---|---|

| Oil Extraction | Pressure Relief Valve | Prevents overpressure in extraction systems | Enhances safety and equipment longevity | Commonly used in offshore platforms |

| Natural Gas Processing | Pressure Reducing Valve | Regulates gas pressure to safe levels | Ensures efficient processing and transportation | Critical for pipeline safety |

| Refinery Operations | Safety Relief Valve | Automates release of excess pressure | Protects equipment from catastrophic failure | Regulatory compliance required |

| Petrochemical Production | Back Pressure Valve | Maintains system pressure during operation | Optimizes chemical reaction processes | Enhances product yield |

| Water Injection | Pressure-Control Valve | Regulates water injection rates | Increases oil recovery efficiency | Integrates with advanced monitoring systems |

Enhancing Efficiency: Pressure Valve Uses in Chemical Manufacturing Facilities

In chemical manufacturing facilities, pressure valves play a crucial role in enhancing operational efficiency and safety. These devices are essential for maintaining safe pressure levels within reactors and pipelines, preventing potential explosions or catastrophic failures. With advancements in technology, modern pressure valves now feature precision monitoring systems that enable real-time adjustments and automated responses to fluctuating conditions, thus streamlining production processes.

The growing demand for efficient chemical processes has led to innovations in valve technology, making them integral to sustainability efforts as well. By optimizing the use of pressure relief valves, facilities can minimize waste and reduce the energy consumption associated with traditional manufacturing methods. Furthermore, the integration of artificial intelligence in monitoring pressure systems allows for predictive maintenance, enhancing reliability while decreasing operational costs over time. As industries strive towards greater safety and sustainability, pressure valves remain a key component in achieving these goals.

Case Studies: Pressure Valve Solutions in Food and Beverage Processing Industries

In the food and beverage processing industries, pressure valves play a crucial role in maintaining optimal operational efficiency while ensuring safety and compliance with health regulations.

These valves control the pressure of fluids during various stages of production, such as in pasteurization, fermentation, and packaging processes.

For example, automated pressure relief valves are used in pasteurizers to quickly adjust pressure levels, preventing product spoilage and ensuring the safety of the final product.

Tips: When selecting a pressure valve for your food and beverage application, consider factors such as the fluid type, temperature, and pressure range.

It's vital to choose materials that are compatible with your products, avoiding any contamination.

Additionally, regular maintenance and monitoring of pressure valves are essential for preventing unexpected failures.

Implement a routine inspection schedule to ensure all valves are functioning correctly and replace any parts that show signs of wear.

This proactive approach will enhance the reliability of your processing system and uphold the quality of your products.

Emerging Trends in Pressure Valve Technologies for Renewable Energy Systems

As the world increasingly shifts towards renewable energy, the role of pressure valves in these systems is becoming more critical. Recent reports from the Global Renewable Energy Trends 2023 indicate that the adoption of advanced pressure valve technologies is expected to grow at a compound annual growth rate (CAGR) of 7.5% over the next five years. This growth is driven by the need for efficient energy management, especially in industries such as solar and wind power, where pressure regulation is vital for maintaining system performance and safety.

Modern pressure valves are now engineered with smart technologies that facilitate real-time monitoring and control. For instance, the integration of IoT sensors in these valves allows for predictive maintenance, significantly reducing downtime and operational costs. A study by the International Energy Agency highlights that utilizing smart pressure management systems can improve energy efficiency by up to 15%. As renewable energy systems continue to evolve, so too will the technologies that drive their efficiency and reliability.

Tip: When selecting pressure valves for renewable energy applications, consider models with advanced control capabilities and diagnostics to ensure optimal performance and maintenance efficiency.

Tip: Stay abreast of technological innovations, as emerging materials and automation features can greatly enhance the longevity and reliability of pressure valves in industrial processes.

Related Posts

-

Emerging Trends in Back Pressure Valve Technology by 2025 and Their Key Advantages for Global Buyers

-

Unlocking Performance: Key Technical Specifications of the Best Back Pressure Valve for Global Buyers

-

5 Essential Tips for Choosing Your Water Pressure Regulator Valve

-

Navigating Import and Export Certifications for the Best Gas Regulators in the Market

-

Understanding Industry Standards for Best Slide Gate Valve Manufacturing Processes

-

Identifying Common Issues with Gas Regulators: Ensuring Safety and Efficiency in Your System