- Products

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

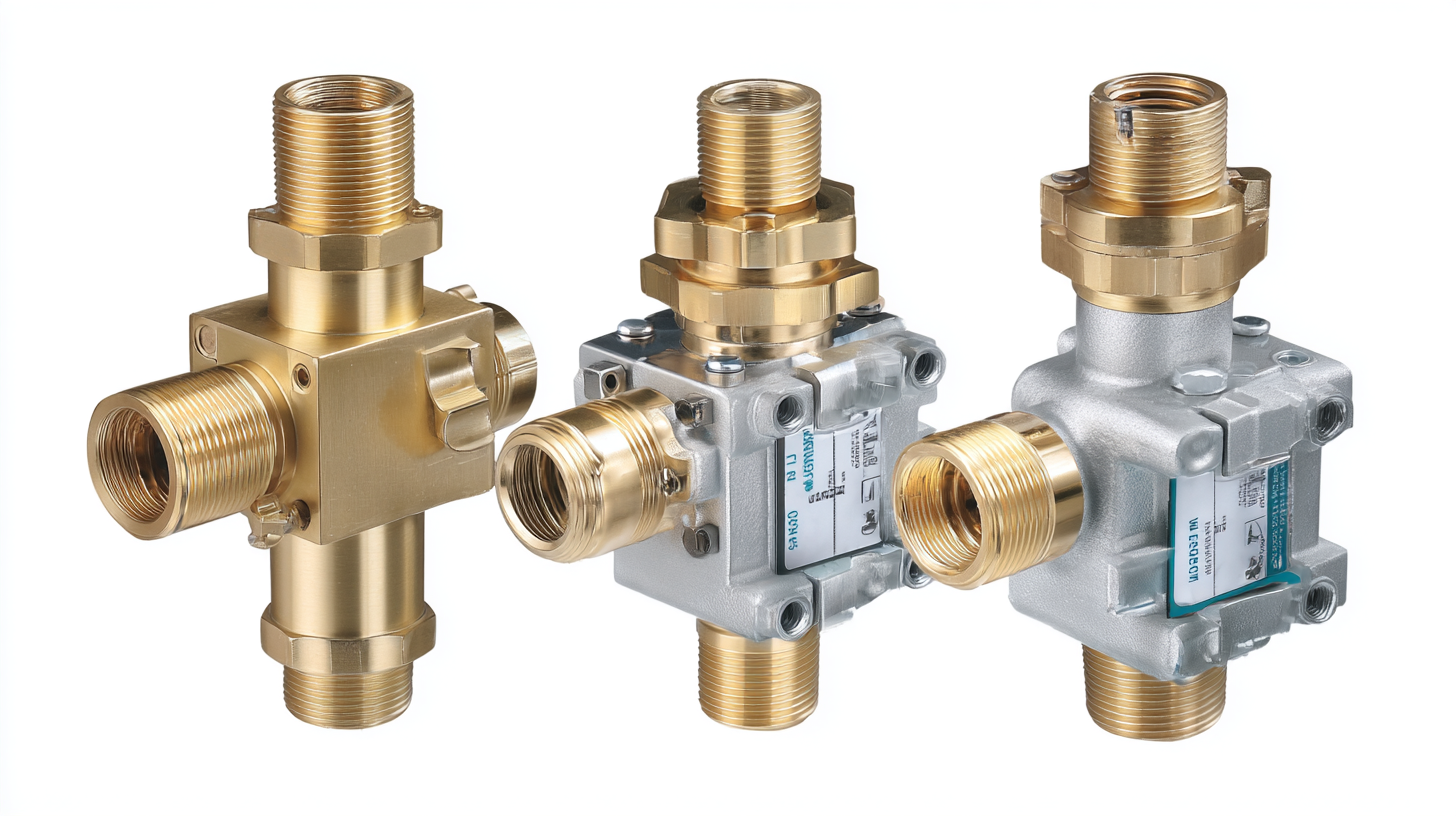

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

Top 5 Innovative Applications of the Best High Pressure Regulators in Various Industries

In an era where industries are evolving rapidly towards increased efficiency and sustainability, high pressure regulators have emerged as vital components across various sectors. According to a recent report by MarketsandMarkets, the global pressure regulator market is expected to reach USD 5.1 billion by 2025, growing at a CAGR of 6.4% during the forecast period. This growth is driven by the rising demand for advanced pressure management solutions in industries such as oil and gas, pharmaceuticals, and food and beverage. High pressure regulators play a crucial role in ensuring safety and performance by controlling and stabilizing pressure in demanding environments.

As we delve into the top five innovative applications of high pressure regulators, we will explore how these technologies not only optimize operational efficiency but also enhance safety and compliance in 2025's rapidly evolving industrial landscape.

Advantages of Exceptional After-Sales Support in High Pressure Regulator Applications

Exceptional after-sales support in high pressure regulator applications is a cornerstone for ensuring optimal performance and reliability across various industries. Comprehensive support can drastically reduce operational downtime, which, according to a report by the International Journal of Production Research, can cost businesses up to $260,000 per hour in manufacturing environments. This data highlights the undeniable value of prompt and effective after-sales service, especially in high-pressure applications where safety and precision are critical.

Tip: Always choose a supplier that offers robust after-sales support, including training for your team and resources for troubleshooting. This can significantly enhance your operational efficiency and reduce the need for costly repairs.

Moreover, industries such as oil and gas, pharmaceuticals, and food processing rely heavily on high pressure regulators. A study published by the American Institute of Chemical Engineers indicates that regular maintenance supported by efficient after-sales services can extend equipment life by as much as 40%. By ensuring that businesses can quickly access expert assistance, they not only uphold safety standards but also maximize their return on investment.

Tip: Consider establishing a maintenance schedule in collaboration with your supplier to regularly assess and service your high pressure regulators. This proactive approach can prevent unexpected failures and ensure a seamless operational flow.

Top 5 Innovative Applications of High Pressure Regulators

This bar chart illustrates the distribution of high pressure regulator applications across various industries. The data indicates that the Oil & Gas industry leads in application percentage, followed by Chemicals and Food Processing. Understanding these applications can highlight the innovative uses of high pressure regulators and the significant impact of exceptional after-sales support across these sectors.

Cost Analysis of Maintenance for High Pressure Regulators Across Industries

The maintenance cost of high pressure regulators is a critical consideration across various industries, especially as sectors like pharmaceuticals and energy strive for efficiency and sustainability. With the global industrial regulators market projected to reach USD 106.3 billion by 2034, companies are increasingly recognizing the importance of maintaining their equipment to prolong service life and reduce downtime. In the pharmaceutical industry, the integration of AI is reshaping how these regulators are monitored, allowing for predictive maintenance strategies that can significantly lower costs and increase reliability.

Moreover, the high pressure washer market is expected to grow to USD 26.9 billion by 2032, highlighting the rising demand for efficient pressure regulation technologies. This growth momentum indicates that industries are investing in advanced regulators that not only enhance performance but also come with lower operational and maintenance costs. As companies adapt to digitalization trends, the focus on smart technologies, including IoT and AI-driven systems, will likely transform maintenance practices, leading to more cost-effective solutions across multiple sectors.

Innovative Solutions for Minimizing Downtime in High Pressure Regulation Systems

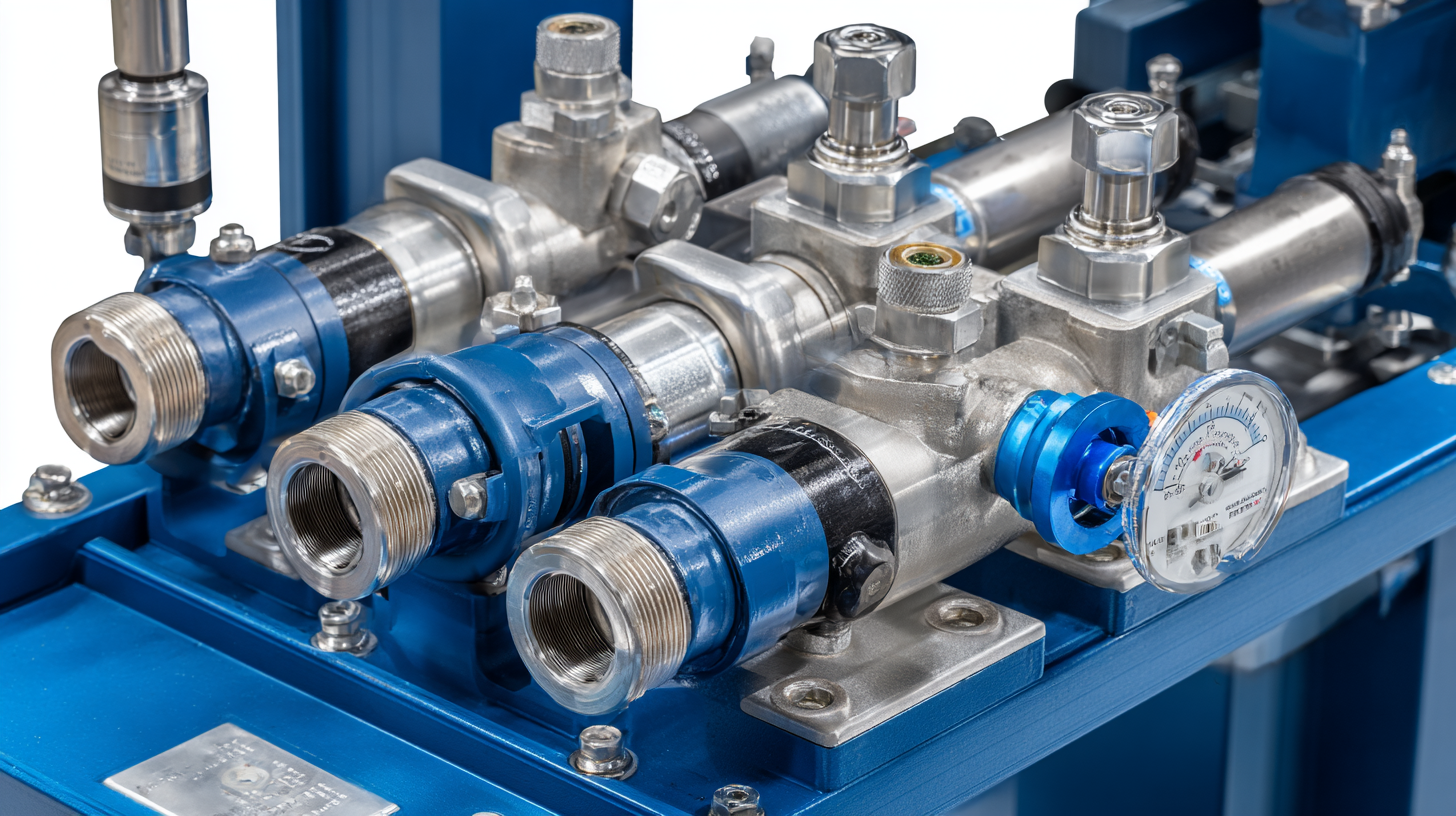

High-pressure regulation systems are vital across various industries, but they often face challenges that can lead to significant downtime. Innovative solutions are being developed to minimize these interruptions, ensuring that processes remain efficient and safe. One such solution is the integration of smart pressure regulators equipped with IoT technology. These regulators can continuously monitor pressure levels and detect anomalies in real time, allowing for proactive adjustments and reducing the risk of failure.

High-pressure regulation systems are vital across various industries, but they often face challenges that can lead to significant downtime. Innovative solutions are being developed to minimize these interruptions, ensuring that processes remain efficient and safe. One such solution is the integration of smart pressure regulators equipped with IoT technology. These regulators can continuously monitor pressure levels and detect anomalies in real time, allowing for proactive adjustments and reducing the risk of failure.

To ensure optimal performance, companies can implement regular maintenance schedules and training for personnel. A well-trained operator can quickly identify and resolve potential issues before they escalate, which is crucial for minimizing downtime. Additionally, using advanced materials in the construction of regulators can improve their durability and resistance to wear, further enhancing reliability.

Another tip is to incorporate redundancy into pressure regulation systems. By installing backup regulators, industries can ensure that if one unit fails, the system can still operate without significant interruptions. This approach not only maintains the efficiency of the operations but also provides peace of mind, knowing that contingencies are in place for unforeseen circumstances.

Strategies for Enhancing Customer Satisfaction through Quality Repairs

In the age of rapid technological advancement, hotels are increasingly leveraging intelligent systems to enhance the quality of their services. The adoption of artificial intelligence in hotel management not only streamlines operations but also significantly impacts customer satisfaction. By analyzing customer interactions and feedback through AI-driven systems, hotels can identify service quality issues and implement tailored solutions that meet the specific needs of their guests.

One of the key challenges in the hospitality industry is ensuring that the service quality aligns with customer expectations. When intelligent systems can analyze real-time data and predict customer preferences, hotels are better equipped to personalize services, leading to enhanced guest experiences. For instance, AI can facilitate responsive communication, allowing staff to address customer concerns promptly and effectively, which is essential for maintaining high satisfaction levels. This proactive approach to service quality not only fosters a positive relationship with guests but also increases loyalty and encourages repeat visits.

Moreover, the integration of smart technologies allows hotels to conduct thorough evaluations of their service delivery. By employing strategic measures to enhance quality, such as targeted training programs for employees based on AI insights, hotels can continuously improve their service standards. Ultimately, this commitment to leveraging intelligent systems for better service quality underlines the importance of innovation in achieving customer satisfaction in the competitive hospitality landscape.

Evaluating the Long-Term Value of Reliable High Pressure Regulator Services

The longevity and reliability of high pressure regulators are pivotal in various industries, where they serve as critical components for maintaining safety and performance standards. Investing in reliable high pressure regulator services not only ensures consistent operation but also mitigates potential risks associated with pressure fluctuations. For sectors such as chemical processing and pharmaceuticals, precision in pressure control is crucial. Regular maintenance and evaluation can enhance the life expectancy of these regulators, translating into significant cost savings for companies over time.

Moreover, the long-term value of high pressure regulator services extends beyond mere functionality. By prioritizing regular servicing and upgrades, industries can improve operational efficiency and reduce downtime. This proactive approach promotes a culture of safety and accountability, essential factors in highly regulated environments. Ultimately, businesses that recognize the importance of maintaining high pressure regulators will find themselves better positioned to innovate while ensuring compliance with safety regulations, thereby contributing to overall operational excellence.

Top 5 Innovative Applications of the Best High Pressure Regulators in Various Industries - Evaluating the Long-Term Value of Reliable High Pressure Regulator Services

| Application | Industry | Pressure Range (psi) | Material Compatibility | Long-Term Value |

|---|---|---|---|---|

| Gas Distribution | Energy | 0 - 3000 | Stainless Steel, Brass | High |

| Chemical Injection | Chemical | 0 - 1500 | PVC, PTFE | Medium |

| Hydraulic Pressure Control | Manufacturing | 0 - 5000 | Aluminum, Steel | High |

| Welding Applications | Construction | 0 - 500 | Copper, Iron | Medium |

| Food and Beverage Processing | Food Industry | 0 - 1000 | 316 Stainless Steel | High |