- Products

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

Top 10 Temperature Control Valves for Efficient Heating and Cooling Solutions

In the pursuit of energy efficiency and optimal climate control, Temperature Control Valves have emerged as indispensable components in modern heating and cooling systems. According to a recent report published by the International Energy Agency (IEA), heating and cooling account for nearly 50% of global energy consumption in buildings, highlighting the critical need for advanced solutions that not only maintain comfort but also reduce energy wastage. The implementation of high-quality temperature control valves enables system operators to precisely regulate fluid flow and temperature, thereby enhancing the overall efficiency of HVAC systems.

As we look towards 2025, the demand for innovative temperature control solutions is set to escalate, driven by increased regulatory pressures and a growing emphasis on sustainability. A study by MarketsandMarkets indicates that the global market for temperature control valves is anticipated to reach $4.8 billion by 2025, growing at a CAGR of 6.2%. This growth underscores the importance of selecting the right temperature control valves to optimize system performance and operational cost savings. In this article, we will explore the top 10 temperature control valves that represent the cutting edge of technology in providing efficient heating and cooling solutions for various applications.

Top 5 Temperature Control Valves: Key Metrics for Efficient Performance

When considering the efficiency of heating and cooling systems,

temperature control valves (TCVs) play a pivotal role.

According to the latest HVAC industry reports, optimizing performance through TCVs can lead to

energy savings of up to 30% in

commercial buildings. Key metrics that define efficient performance include

flow coefficient (Cv), pressure drop, and temperature adjustment range.

A high Cv value indicates a valve's capability to allow significant flow rate with minimal

pressure loss, which is essential in maintaining consistent temperature control.

Additionally, bi-directional pressure rating and response time are critical in selecting the

right TCV. For instance, a study published in the

Journal of Energy Resources Technology indicated that valves with a

rapid response time can reduce temperature fluctuations by

up to 25%, enhancing comfort levels in

residential setups. Furthermore, modern electronic temperature control valves equipped with smart

technology have shown to improve energy efficiency by allowing real-time adjustments, which can

result in an additional 15% reduction in energy

consumption. Companies adopting these advanced TCVs can not only expect improved performance

but also a notable decrease in overall operational costs.

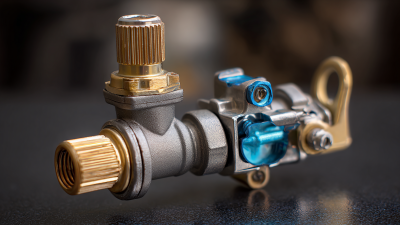

Understanding the Role of Temperature Control Valves in HVAC Systems

Temperature control valves play a vital role in heating, ventilation, and air conditioning (HVAC) systems, ensuring optimal thermal comfort and energy efficiency. These valves regulate the flow of hot or cold fluid within the system, responding dynamically to temperature variations in the environment. By adjusting the flow rate based on real-time temperature readings, they maintain the desired setpoint more accurately, preventing overheating or overcooling. This functionality is essential not only for occupant comfort but also for reducing energy consumption, as more precise control leads to less wasted energy.

Additionally, temperature control valves contribute to the overall performance and longevity of HVAC systems. They prevent issues such as thermal shock and corrosion by minimizing temperature fluctuations and promoting stable operating conditions. In modern HVAC designs, these valves are often integrated with advanced control systems, allowing for better automation and remote monitoring. This integration enhances system responsiveness and paves the way for smart building technologies, further increasing the efficiency of heating and cooling solutions in residential and commercial settings.

Industry Standards for Energy Efficiency in Heating and Cooling Applications

In the pursuit of energy efficiency in heating and cooling applications, temperature control valves play a pivotal role. According to the Energy Information Administration (EIA), approximately 55% of the energy consumed in commercial buildings is dedicated to heating and cooling. This underscores the importance of selecting the right valves that comply with industry standards, including ASHRAE and ISO regulations, which emphasize optimized performance and reduced energy consumption.

Recent studies reveal that implementing advanced temperature control valves can enhance system efficiency by up to 30%. For instance, a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) highlights that properly calibrated valves significantly minimize water and energy wastage, contributing to lower operational costs. Additionally, these valves help meet the stringent regulations set forth by the U.S. Department of Energy (DOE), targeting a 20% improvement in energy efficiency by 2030. Industry professionals are increasingly recognizing that investing in high-quality temperature control valves not only aligns with regulatory requirements but also supports sustainable building practices.

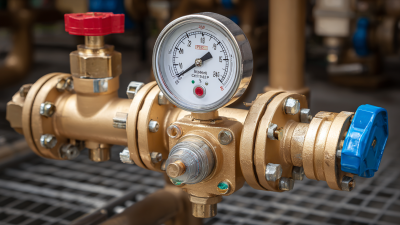

Top 10 Temperature Control Valves for Efficient Heating and Cooling Solutions - Industry Standards for Energy Efficiency in Heating and Cooling Applications

| Model | Temperature Range (°C) | Body Material | Energy Efficiency Rating | Pressure Rating (bar) | Applications |

|---|---|---|---|---|---|

| Model A | -10 to 120 | Brass | A+ | 16 | Residential Heating |

| Model B | 0 to 150 | Stainless Steel | A | 10 | Industrial Cooling |

| Model C | -20 to 100 | PVC | B | 8 | Aquaculture Systems |

| Model D | -5 to 120 | Bronze | A++ | 12 | HVAC Systems |

| Model E | 10 to 180 | Aluminum | A+ | 15 | Commercial Plumbing |

| Model F | -30 to 90 | Cast Iron | A | 14 | Chemical Processing |

| Model G | -10 to 160 | Nylon | B+ | 9 | Refrigeration |

| Model H | 5 to 130 | Copper | A++ | 11 | Food Processing |

| Model I | -40 to 100 | PFA | A | 7 | Pharmaceuticals |

| Model J | -20 to 220 | Carbon Steel | A++ | 13 | Energy Recovery Systems |

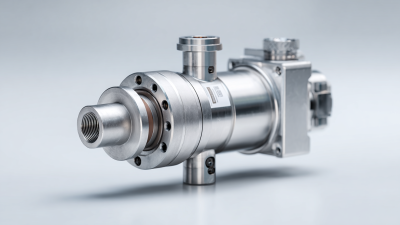

Comparative Analysis of Material Durability in Temperature Control Valves

Temperature control valves are crucial components in HVAC systems, directly impacting their efficiency and performance. When selecting a valve, material durability should be a primary consideration, as it affects the valve's longevity and reliability. Common materials used in these valves include brass, stainless steel, and plastic, each offering unique advantages and limitations regarding durability.

Brass valves are renowned for their corrosion resistance and strength, making them suitable for high-pressure applications. However, they may not perform as well in extremely hot or cold environments. Stainless steel is often regarded as the most durable option, capable of withstanding harsh conditions without succumbing to wear. Its resistance to rust and high temperatures makes it ideal for both heating and cooling systems. On the other hand, plastic valves tend to be lighter and less expensive but are generally less durable compared to metal counterparts. They may degrade over time when exposed to extreme temperatures or chemicals, limiting their application in more demanding environments.

Overall, the choice of material in the construction of temperature control valves directly relates to their performance and lifespan. Understanding the comparative durability of these materials helps engineers and technicians make informed decisions, ensuring efficient heating and cooling solutions that meet the long-term demands of various applications.

Innovative Technologies Driving Temperature Control Valve Efficiency in 2023

In 2023, the landscape of temperature control valves is being transformed by innovative technologies that enhance efficiency in heating and cooling systems. These advancements focus on improving responsiveness and precision, enabling systems to adapt quickly to changing temperature demands. Smart sensors and IoT integration are at the forefront, allowing for real-time data collection and analysis. This not only facilitates better control of energy consumption but also minimizes waste, resulting in more sustainable operation.

Moreover, the development of advanced materials and designs is optimizing the performance of temperature control valves. Materials that withstand high temperatures and pressures while maintaining durability are crucial, especially in industrial applications. Additionally, the integration of machine learning algorithms is enhancing predictive maintenance, thereby reducing downtime and extending the lifespan of these critical components.

As a result, both residential and commercial heating and cooling solutions are becoming more efficient, leading to reduced energy costs and an overall lower environmental impact.

Related Posts

-

Unlocking Performance: Key Technical Specifications of the Best Back Pressure Valve for Global Buyers

-

Emerging Trends in Back Pressure Valve Technology by 2025 and Their Key Advantages for Global Buyers

-

Understanding the Essential Role of Pressure Regulator Valves in Industrial Applications

-

The Ultimate Guide to Understanding Water Pressure Regulators: How They Enhance Your Plumbing System

-

The Essential Guide to Choosing the Right Gas Regulator Valve for Your Needs

-

How to Choose the Right Pressure Regulator for Your Industrial Needs